- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-16 Origin: Site

CNC routers have become an essential tool in various industries due to their ability to automate the cutting, carving, and shaping of materials with high precision. But, as their adoption grows, many people wonder: "Are CNC routers worth it?" This question requires a deeper look into the costs, benefits, and applications of these machines. In this article, we will explore these factors to help you evaluate whether investing in a CNC router is the right decision for you, whether you're a hobbyist, a small business owner, or running a larger manufacturing operation.

A CNC (Computer Numerical Control) router is an advanced machine tool that uses automated processes to cut, carve, or shape materials such as wood, metal, plastic, foam, and even stone. Unlike traditional tools, CNC routers are operated through digital instructions, which are created using CAD (Computer-Aided Design) software and converted into machine code by CAM (Computer-Aided Manufacturing) software. The machine then follows these instructions with pinpoint accuracy.

Key features of CNC routers include:

Precision and Automation: CNC routers can perform repetitive tasks with high precision, ensuring uniform results across large production runs.

Multi-material Compatibility: These routers can cut through a variety of materials, including wood, metal, plastics, and composites, making them highly versatile.

Customization: With the ability to change designs via software, CNC routers can easily switch between different projects without significant downtime or retooling.

These features make CNC routers invaluable for a wide range of industries, from woodworking and signage to automotive and aerospace.

The process begins with a digital design created in CAD software. Once the design is complete, the CAD file is transferred to CAM software, which converts the design into a set of instructions the CNC router can follow. These instructions are typically in the form of G-code, a standard machine language used to control the movement of the router's spindle and cutting tools.

The router then moves along multiple axes (usually X, Y, and Z) to execute the cuts. More advanced machines may have additional axes (4th or 5th) for more intricate work, such as 3D milling and carving. The CNC router's spindles spin the cutting tools at high speeds, allowing them to slice through materials with precision, while the machine automatically adjusts speed, depth, and other parameters to ensure the perfect cut.

CNC routers are available in various types, each suited for different materials and tasks. Common types include:

| Type of CNC Router | Primary Material | Typical Applications |

|---|---|---|

| Wood CNC Routers | Wood | Furniture making, cabinetry, signage, decorative arts |

| Stone CNC Routers | Stone, Marble, Granite | Tombstones, sculptures, countertops, custom carvings |

| Metal CNC Routers | Metals (Aluminum, Brass, Copper) | Metal molds, automotive parts, aerospace components |

| Multi-material CNC Routers | Wood, Metal, Plastics | Versatile, used for diverse applications across industries |

These machines are used in industries like manufacturing, prototyping, advertising, and art, where precision and efficiency are critical.

One of the most significant advantages of CNC routers is their ability to consistently produce high-quality parts. With a CNC router, precision is guaranteed, and the margin for error is minimized. Whether you're cutting complex patterns or simple shapes, the machine will repeat the exact process each time. This consistency ensures that the final product meets the required specifications, which is especially crucial in industries like custom furniture making or high-precision parts manufacturing.

Additionally, CNC routers can produce parts with tolerances as tight as 0.01mm, far surpassing the accuracy of manual cutting methods. This high precision is one of the main reasons CNC routers are widely used for high-end projects requiring detailed and accurate work.

CNC routers drastically improve productivity. By automating cutting, carving, and engraving tasks, they allow businesses to complete projects faster and with less human intervention. A CNC router can work around the clock, only needing supervision to ensure it runs smoothly.

Furthermore, CNC routers reduce the time spent on repetitive tasks. Once a design is programmed, the machine can automatically produce the same part multiple times without any further input, saving time on each subsequent piece. This is particularly beneficial for industries that require mass production or the creation of identical components.

CNC routers are incredibly versatile, allowing for the creation of a wide range of designs. Whether you're making custom furniture, intricate signage, or even 3D prototypes, CNC routers can handle it all. The ability to easily switch between projects is one of the primary benefits of these machines, making them a flexible solution for businesses in various sectors.

For instance, in the woodworking industry, CNC routers are used to produce everything from cabinetry and furniture to custom moldings and detailed carvings. Similarly, in signage, the machine can create 2D or 3D designs with intricate detailing that would be challenging or time-consuming to achieve manually.

CNC routers help optimize material usage by minimizing waste during the cutting process. Using nesting software, CNC routers can arrange parts on a sheet of material in a way that maximizes the use of the raw material. This results in less scrap and lowers material costs in the long run.

Additionally, the high precision of CNC routers means fewer mistakes are made, leading to less rework and reduced material waste due to errors. Over time, these savings can add up significantly.

As your business grows, so does your need for increased production capacity. CNC routers offer scalability by allowing you to produce larger quantities of parts without significantly increasing labor costs. Since the machine operates on digital instructions, adjusting for increased production or product changes is relatively easy.

For businesses that plan to expand their operations, investing in a CNC router ensures they are prepared for future growth without the need to hire additional staff or invest in multiple machines.

The initial cost of purchasing a CNC router can vary greatly depending on the machine’s size, features, and intended use. Entry-level models can start at around $2,000 for smaller machines designed for hobbyists. For industrial-grade machines used in commercial operations, prices can range from $10,000 to over $100,000.

The price also depends on factors like the number of axes, spindle power, and additional capabilities such as automatic tool changers. Along with the router itself, you must also factor in the cost of software, tools, and accessories required to run the machine.

In addition to the initial investment, CNC routers come with ongoing operational costs. These include:

Tool replacements: CNC router tools wear out over time and need to be replaced periodically.

Software subscriptions: Many CAD/CAM programs require annual licensing fees, which add to the total cost of ownership.

Power consumption: Large machines can consume a significant amount of electricity, especially during high-speed operations.

CNC routers require specialized knowledge in CAD and CAM software, as well as an understanding of machine operation. For businesses that are new to CNC technology, there may be an upfront cost in training employees to operate the machines effectively.

CNC routers require a dedicated workspace, including stable flooring, proper power supply, and adequate ventilation for dust collection. Larger machines may also require additional space for material storage and handling.

Small businesses that need to produce custom items, such as furniture or signage, can greatly benefit from the speed and efficiency of CNC routers. These machines help businesses reduce the time it takes to complete a project, thus increasing profitability by allowing them to take on more orders.

For small businesses looking to scale, a CNC router provides the flexibility to increase production without needing to hire additional labor. The ability to produce high-quality, customized products quickly and at scale helps businesses stay competitive in their market.

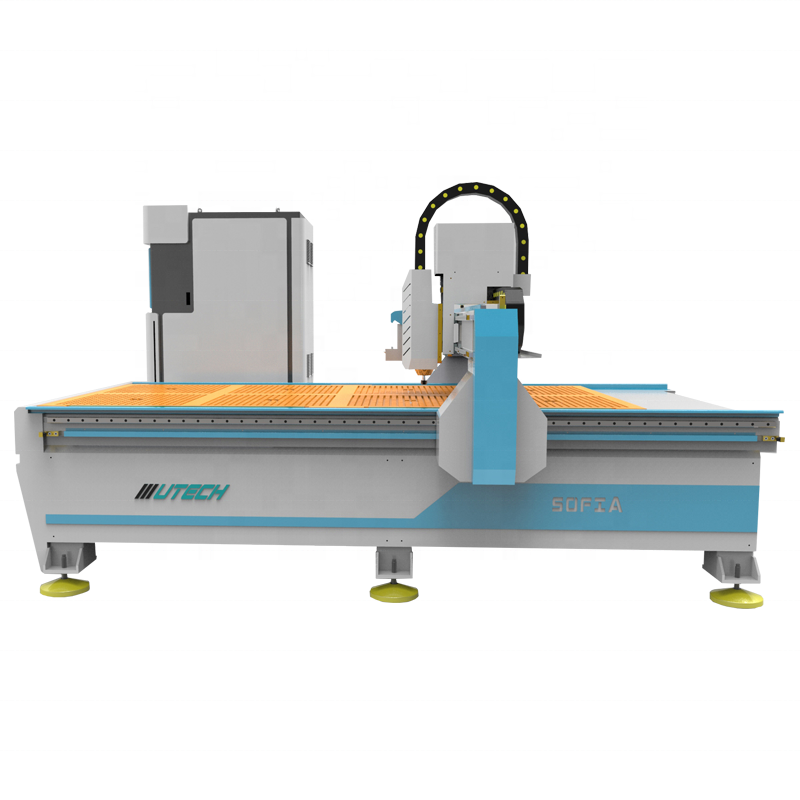

CNC routers are incredibly valuable tools for those needing precision, efficiency, and scalability. However, they come with considerable upfront costs and require ongoing maintenance and training. If your business or hobby requires frequent, high-precision work, a CNC router is likely worth the investment. Whether you're a hobbyist seeking to explore new creative avenues or a small business owner aiming to scale operations, a CNC router can help elevate your work to new levels of quality and efficiency. UTECH's advanced CNC routers provide unmatched value, ensuring enhanced performance and long-term reliability for any project.

A: CNC routers are computer-controlled machines used to cut, carve, and shape materials such as wood, metal, and plastic with high precision.

A: CNC routers provide efficiency, precision, and scalability, making them a valuable investment for businesses and hobbyists requiring consistent, high-quality results.

A: CNC routers vary in price, with entry-level models starting at around $2,000 and industrial machines costing upwards of $100,000, depending on features and capabilities.

A: CNC routers require training and knowledge of CAD/CAM software, but once mastered, they significantly increase productivity and precision in production tasks.

A: Yes, CNC routers are versatile, capable of handling both small-scale custom projects and large production runs with consistent quality.