- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

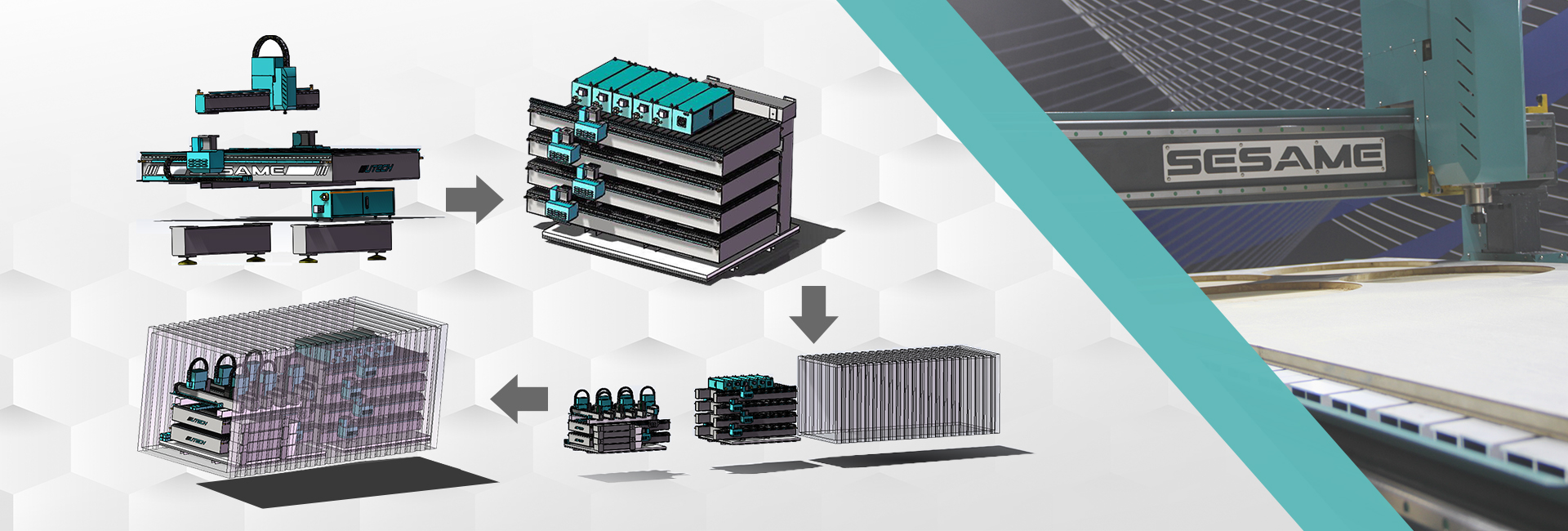

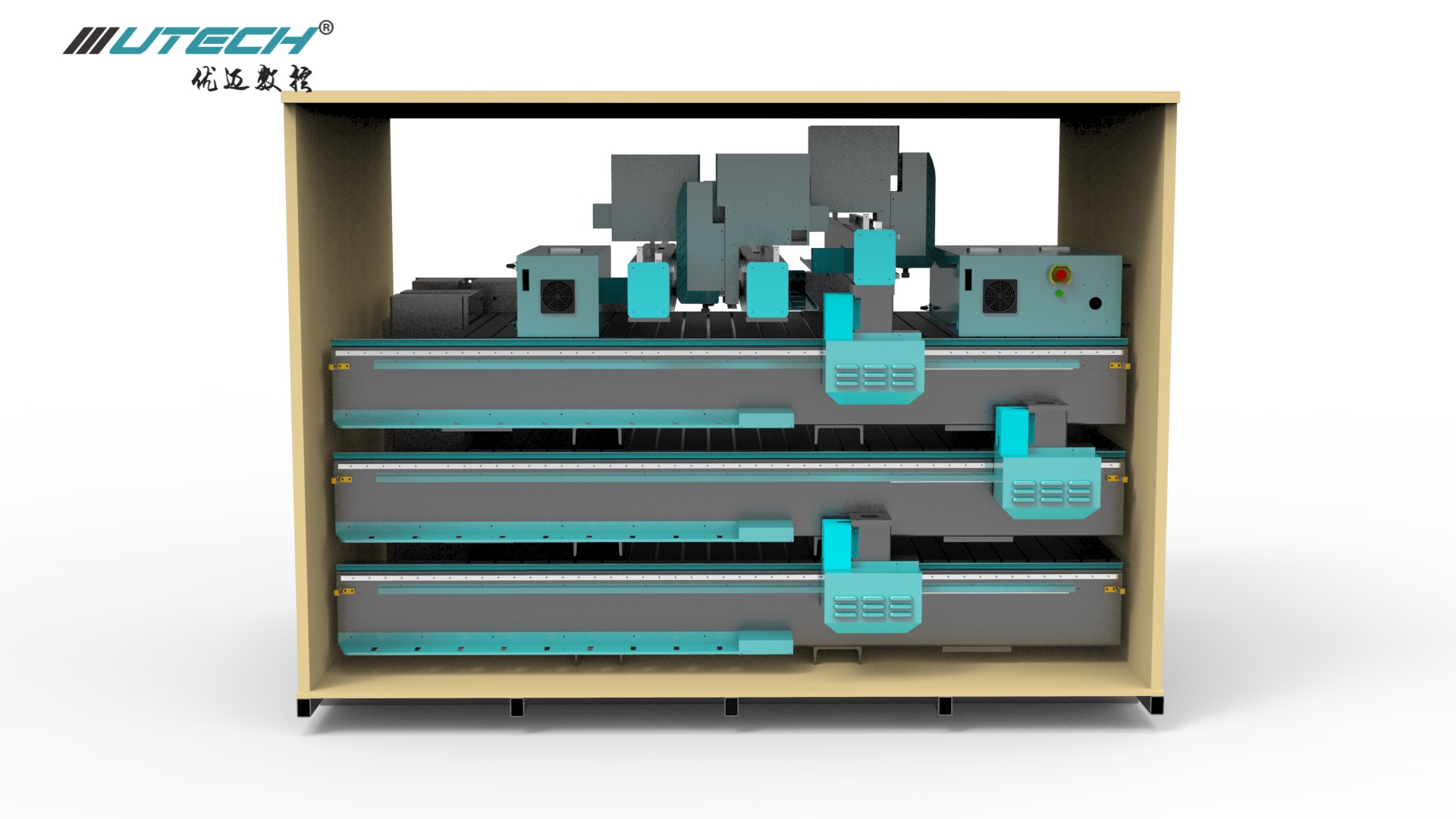

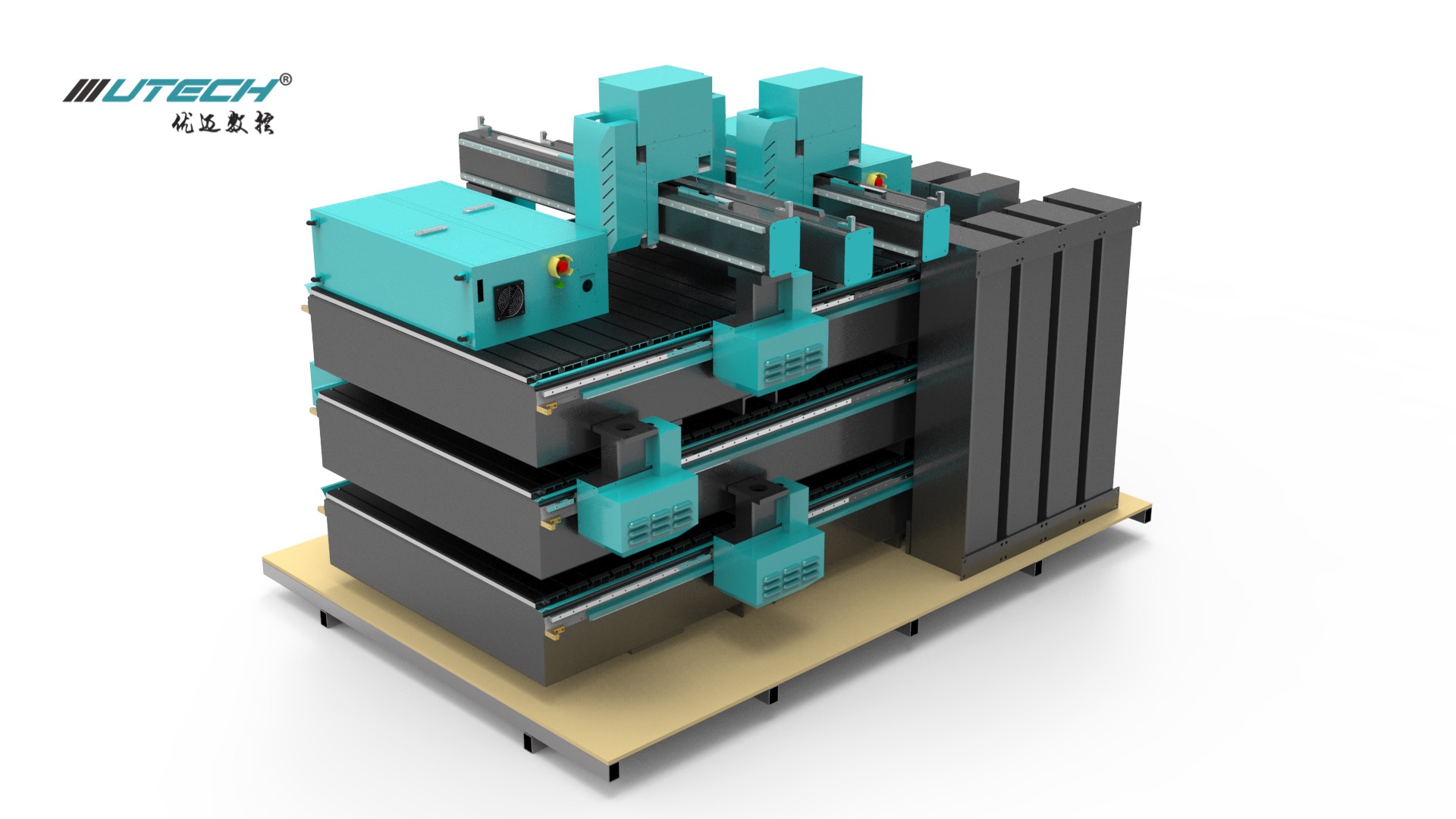

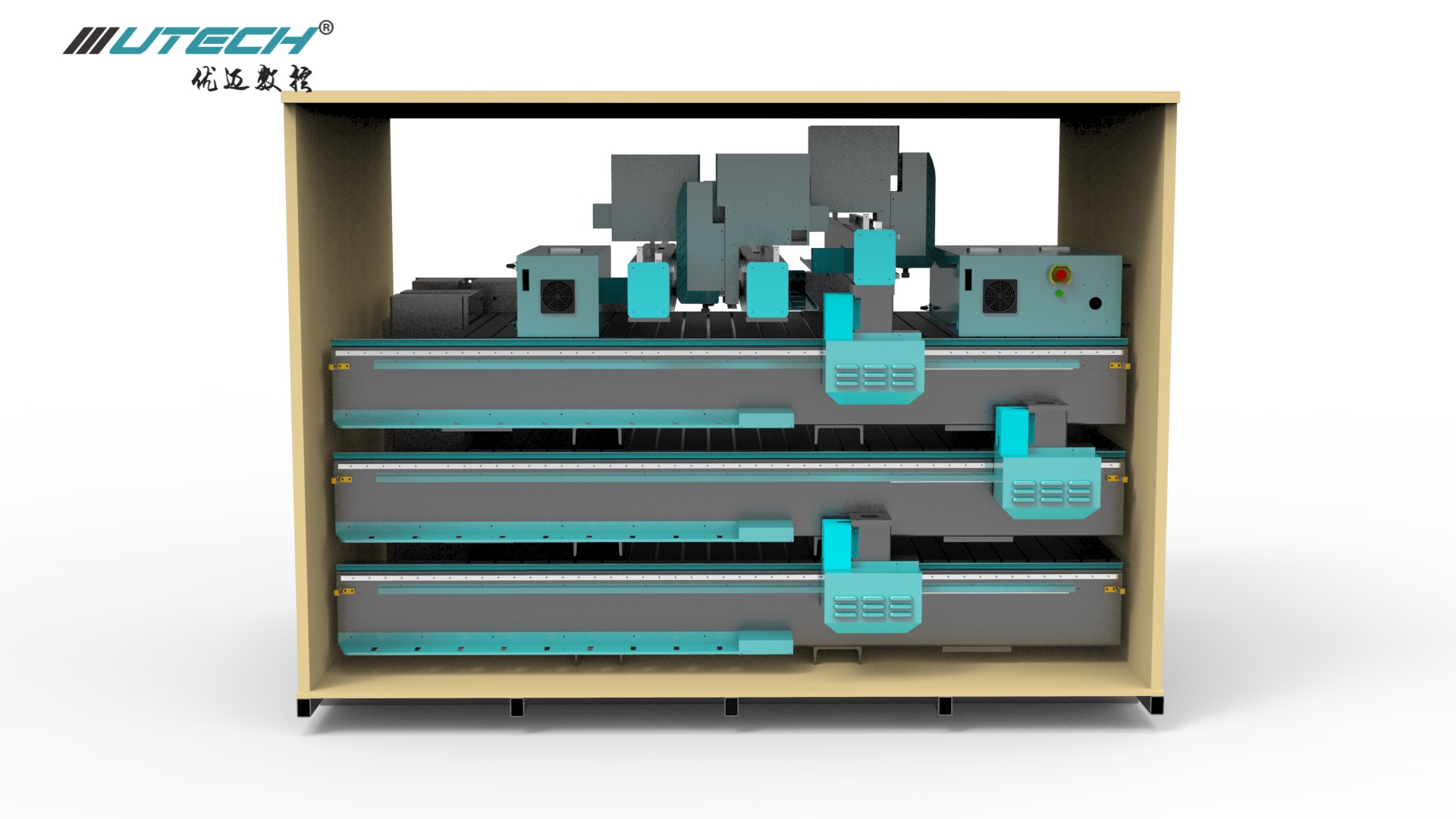

Before confirming the production order, we will provide the rendering picture and 360-degree panoramic video, so that customers can fully understand the style and structure of the machine, so as to ensure that the actual machine meets the requirements of customers, so as to avoid the discrepancy between the real object and customers' imagination caused by various communication deviations.

UTECH technical support is designed to help you make the most of the machine. A variety of technical files and installation videos will be placed in the U disk and shipped with the machine. Our technical experts can provide online remote support and training, and contact UTECH technical support experts in real-time for remote diagnosis. Door-to-door service is also available.

Feel free contact us if you have questions: Emily: 86-135763178585

| Size: | |

|---|---|

| Spindle Motor: | |

| XYZ Transmission: | |

| Drive&Motor: | |

| Machine Table: | |

| Availability: | |

UT-1325

UTECH

2021132503

Hot Sale! Wood Carving Machine Cnc Router 6090 1212 1313 1325 2030 2040

Characteristics

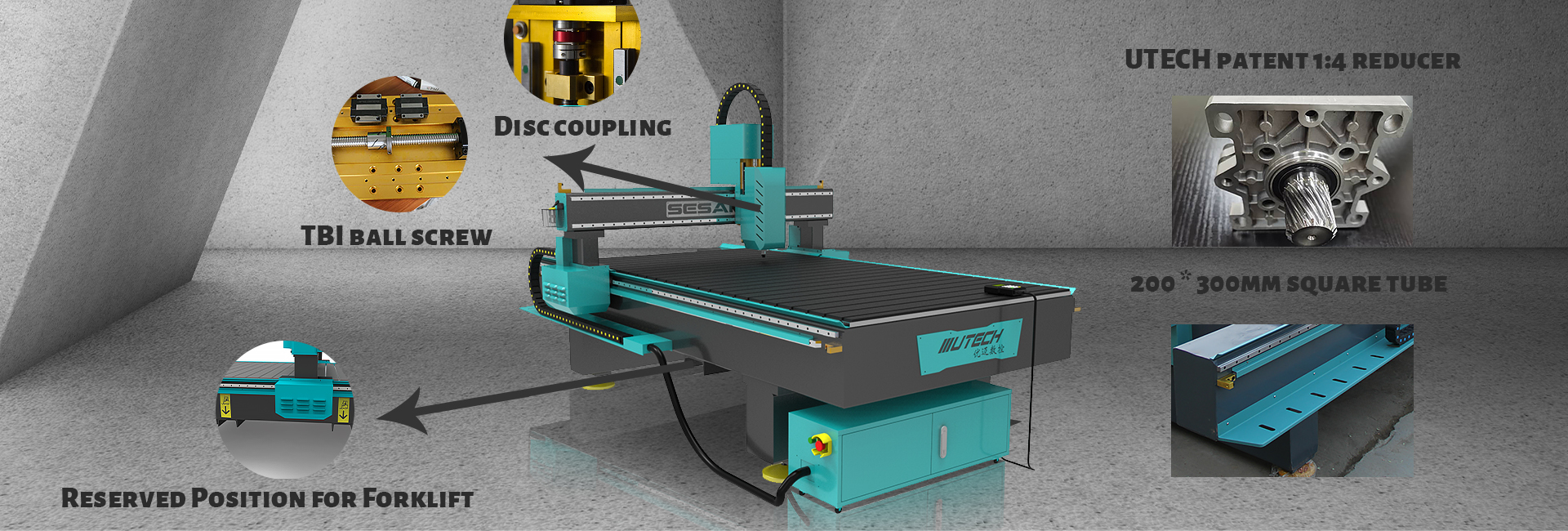

The UTECH SESAME Series CNC Router is engineered for professional woodworking, delivering stable performance, long-term durability and high-precision machining. Built with a heavy-duty 200×300mm welded steel bed, cast-iron columns and a 150×200mm reinforced gantry, the machine ensures exceptional rigidity for cutting hardwood, MDF and composite panels. Its precision reducer system provides low backlash, low noise and highly accurate motion control—significantly outperforming gear-driven and belt-driven structures in stability and lifespan. Equipped with high-precision linear guides and CNC-machined aviation-grade aluminum head components, the SESAME router offers smoother axis movement, stronger motor torque and sustained cut quality even in long-hour production. Assembled by UTECH’s professional calibration team, the machine guarantees ±0.01mm repeat positioning accuracy, making it a reliable, high-efficiency solution for cabinetry, furniture production and custom woodcraft manufacturing.

Parameter list

Descriptions | Parameters | |||

Model | SESAME S2 1325 | SESAME S2 1530 | SESAME S2 2030 | SESAME S2 2040 |

Working area | 1300*2500mm | 1500*3000mm | 2000*3000mm | 2000*4000mm |

Accuracy | ±0.05mm | |||

Table Surface | T-slot table (vacuum table is optional) | |||

Frame | Square pipe welding bed structure 200*300mm+150*200mmgantry | |||

X, Y Structure | 1.25M Gear and rack transmission, Taiwan Linear Rail | |||

Z Structure | Taiwan TBI Ball Screw, Taiwan Linear Rail | |||

Spindle Power | 4.5kw air cooled spindle+ER25 cutter | |||

Spindle Speed | 0-24000RPM | |||

Drive Motors | JMC stepper motor and driver | |||

Working Voltage | AC 220/380V | |||

Command Language | G Code | |||

Operating System | HD100 handle controller (DSP or Mach3 optional) | |||

Computer Interface | Ethernet (or USB) | |||

Inverter | Best | |||

Software | Vectric Aspire/Type 3 /Artcam /Ucancam/JDPaint | |||

Hot Sale! Wood Carving Machine Cnc Router 6090 1212 1313 1325 2030 2040

Characteristics

The UTECH SESAME Series CNC Router is engineered for professional woodworking, delivering stable performance, long-term durability and high-precision machining. Built with a heavy-duty 200×300mm welded steel bed, cast-iron columns and a 150×200mm reinforced gantry, the machine ensures exceptional rigidity for cutting hardwood, MDF and composite panels. Its precision reducer system provides low backlash, low noise and highly accurate motion control—significantly outperforming gear-driven and belt-driven structures in stability and lifespan. Equipped with high-precision linear guides and CNC-machined aviation-grade aluminum head components, the SESAME router offers smoother axis movement, stronger motor torque and sustained cut quality even in long-hour production. Assembled by UTECH’s professional calibration team, the machine guarantees ±0.01mm repeat positioning accuracy, making it a reliable, high-efficiency solution for cabinetry, furniture production and custom woodcraft manufacturing.

Parameter list

Descriptions | Parameters | |||

Model | SESAME S2 1325 | SESAME S2 1530 | SESAME S2 2030 | SESAME S2 2040 |

Working area | 1300*2500mm | 1500*3000mm | 2000*3000mm | 2000*4000mm |

Accuracy | ±0.05mm | |||

Table Surface | T-slot table (vacuum table is optional) | |||

Frame | Square pipe welding bed structure 200*300mm+150*200mmgantry | |||

X, Y Structure | 1.25M Gear and rack transmission, Taiwan Linear Rail | |||

Z Structure | Taiwan TBI Ball Screw, Taiwan Linear Rail | |||

Spindle Power | 4.5kw air cooled spindle+ER25 cutter | |||

Spindle Speed | 0-24000RPM | |||

Drive Motors | JMC stepper motor and driver | |||

Working Voltage | AC 220/380V | |||

Command Language | G Code | |||

Operating System | HD100 handle controller (DSP or Mach3 optional) | |||

Computer Interface | Ethernet (or USB) | |||

Inverter | Best | |||

Software | Vectric Aspire/Type 3 /Artcam /Ucancam/JDPaint | |||

Machine details

Machine details

Applicable industries

The SESAME series CNC engraving machine excels in multiple industries thanks to its high precision, high stability, and powerful cutting capabilities, and is particularly suitable for the following fields:

1. Woodworking: Used for processing cabinet doors, furniture parts, solid wood reliefs, stair railings, decorative moldings, background walls, etc., suitable for various wood materials such as softwood, hardwood, plywood, and MDF.

2. Sign Making: Efficiently processes acrylic letters, lightbox panels, PVC boards, KT boards, two-color boards, etc., with smooth, burr-free cut edges, suitable for advertising lettering, directional signs, and display rack production.

3. Mold Processing: Suitable for processing lightweight molds such as wooden molds, foam molds, and shoe molds, achieving delicate processing results thanks to high-precision guide rails and a stable machine body.

4. Packaging & Models Industry: Suitable for carving honeycomb panels, foam, sandwich panels, and other materials, widely used in packaging models, architectural models, and craft models.

5. Decorative Arts Industry: Suitable for small-batch, diversified production of various artistic sculptures, background wall designs, craft processing, and custom decorative parts.

Applicable industries

The SESAME series CNC engraving machine excels in multiple industries thanks to its high precision, high stability, and powerful cutting capabilities, and is particularly suitable for the following fields:

1. Woodworking: Used for processing cabinet doors, furniture parts, solid wood reliefs, stair railings, decorative moldings, background walls, etc., suitable for various wood materials such as softwood, hardwood, plywood, and MDF.

2. Sign Making: Efficiently processes acrylic letters, lightbox panels, PVC boards, KT boards, two-color boards, etc., with smooth, burr-free cut edges, suitable for advertising lettering, directional signs, and display rack production.

3. Mold Processing: Suitable for processing lightweight molds such as wooden molds, foam molds, and shoe molds, achieving delicate processing results thanks to high-precision guide rails and a stable machine body.

4. Packaging & Models Industry: Suitable for carving honeycomb panels, foam, sandwich panels, and other materials, widely used in packaging models, architectural models, and craft models.

5. Decorative Arts Industry: Suitable for small-batch, diversified production of various artistic sculptures, background wall designs, craft processing, and custom decorative parts.

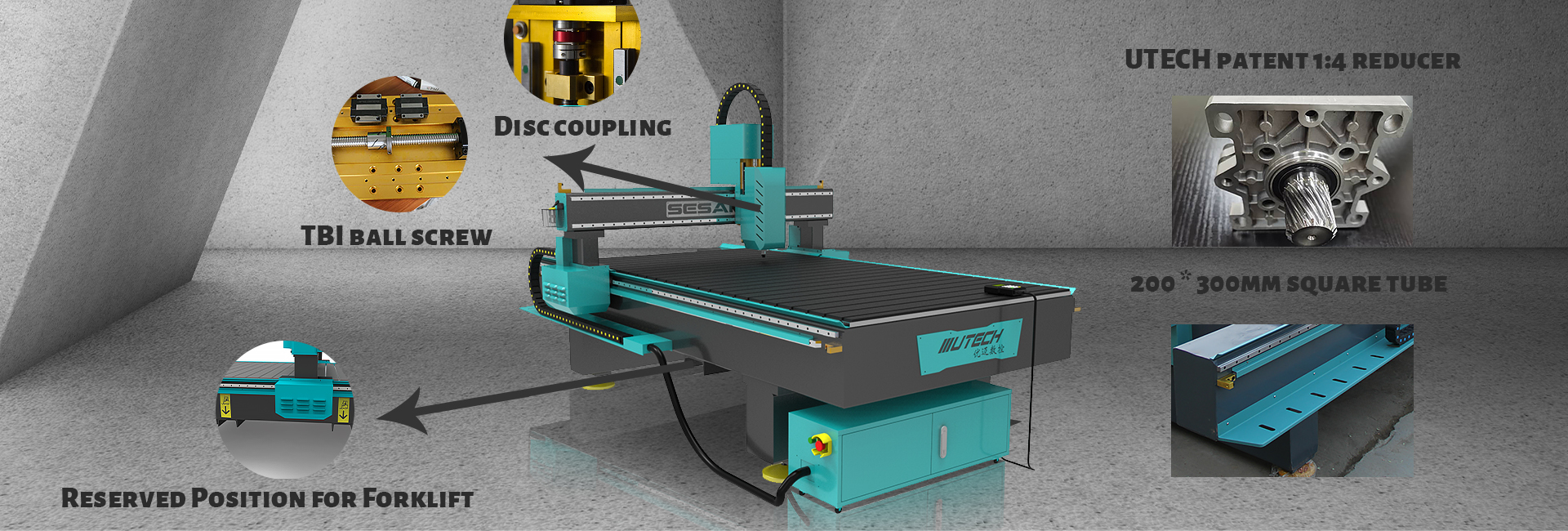

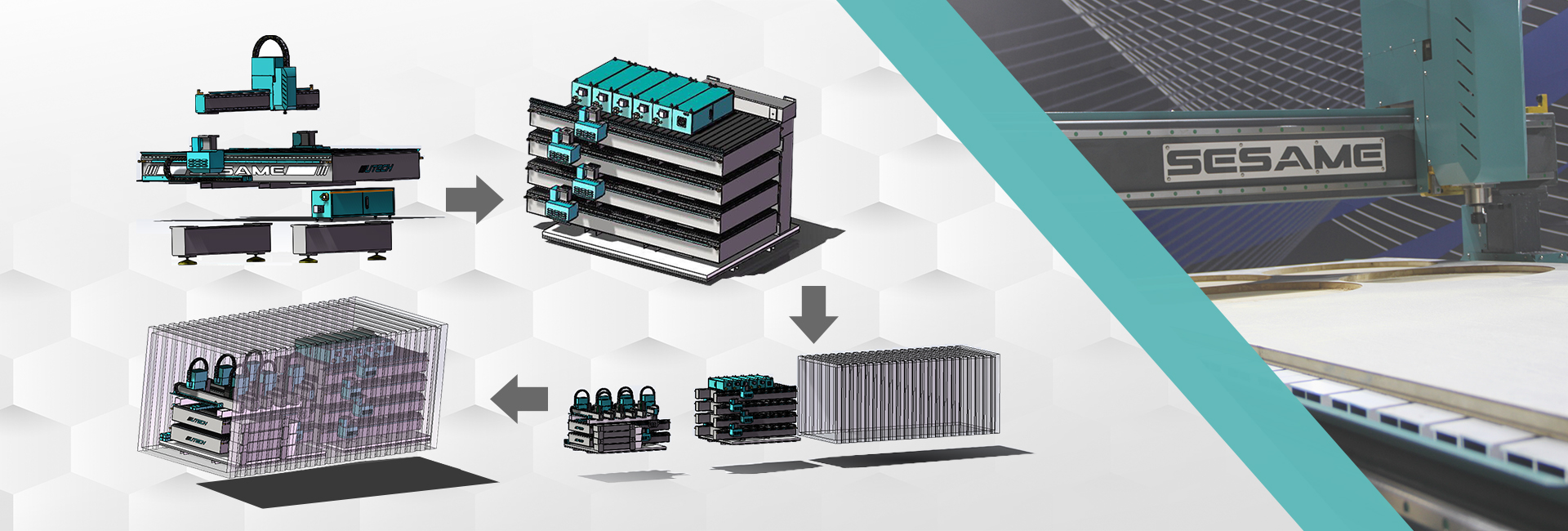

Packing & Delivery

Packing:

1/ If the machine is delivered via LCL, then would be packed with wrapping film, EPE foam, and a standard export plywood box.

2/ If machine delivery via FCL, then don't need a wood box, would be packed with wrapping film and EPE foam.

Shipping:

We support machine delivery via express, air transportation, land transportation, and sea transportation.

1/ Such as some small machine, Mini CNC Router or Small CO2 Laser Machine and Fiber Laser Marking Machine, usually delivered via express and air transportation.

2/ If you wanna us to help you deliver to a domestic warehouse or Russia, Kazakhstan, etc, usually delivered via land transportation.

3/ Large machines or some countries where shipping is more convenient, usually suggest choosing sea transportation.

You can choose any way you'd prefer, we also will give you some proper suggestions.

Packing & Delivery

Packing:

1/ If the machine is delivered via LCL, then would be packed with wrapping film, EPE foam, and a standard export plywood box.

2/ If machine delivery via FCL, then don't need a wood box, would be packed with wrapping film and EPE foam.

Shipping:

We support machine delivery via express, air transportation, land transportation, and sea transportation.

1/ Such as some small machine, Mini CNC Router or Small CO2 Laser Machine and Fiber Laser Marking Machine, usually delivered via express and air transportation.

2/ If you wanna us to help you deliver to a domestic warehouse or Russia, Kazakhstan, etc, usually delivered via land transportation.

3/ Large machines or some countries where shipping is more convenient, usually suggest choosing sea transportation.

You can choose any way you'd prefer, we also will give you some proper suggestions.

FAQ

Q: How do I operate the machine? Is it difficult?

A: Not difficult. We provide:

English operating interface

A user-friendly control system (handheld/PC)

Free online training for new customers

Most customers can become proficient in operating the machine in 1-2 days.

Q: What optional functions can be added to the machine?

A: Common optional configurations include:

Automatic tool changer (ATC)

CCD camera automatic edge finding

Vibrating blade (for cutting soft materials)

Vacuum suction table

Fourth-axis rotary device

We will customize the configuration to suit your industry needs.

Q: How long is the warranty period for the machine? What is the after-sales service like?

A: 1-year warranty on the whole machine (special accessories are subject to separate explanation)

Key components such as the laser/spindle are covered by manufacturer warranty

7×24 online technical support

Lifetime technical guidance

Q: How long does it take to ship the machine? Is the transportation safe?

A: Usually 7-20 days for shipping (depending on the configuration).

Product packaging is divided into three layers. The outer box is made of wood craft box.In the middle, the machine is covered with foam to protect it from vibration. The inner layer is waterproof and moisture-proof with thickened plastic bags.

FAQ

Q: How do I operate the machine? Is it difficult?

A: Not difficult. We provide:

English operating interface

A user-friendly control system (handheld/PC)

Free online training for new customers

Most customers can become proficient in operating the machine in 1-2 days.

Q: What optional functions can be added to the machine?

A: Common optional configurations include:

Automatic tool changer (ATC)

CCD camera automatic edge finding

Vibrating blade (for cutting soft materials)

Vacuum suction table

Fourth-axis rotary device

We will customize the configuration to suit your industry needs.

Q: How long is the warranty period for the machine? What is the after-sales service like?

A: 1-year warranty on the whole machine (special accessories are subject to separate explanation)

Key components such as the laser/spindle are covered by manufacturer warranty

7×24 online technical support

Lifetime technical guidance

Q: How long does it take to ship the machine? Is the transportation safe?

A: Usually 7-20 days for shipping (depending on the configuration).

Product packaging is divided into three layers. The outer box is made of wood craft box.In the middle, the machine is covered with foam to protect it from vibration. The inner layer is waterproof and moisture-proof with thickened plastic bags.