- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-18 Origin: Site

Purchasing a CNC machine is a significant decision for any business, as it directly impacts production efficiency and quality. Are you ready to make the right choice for your manufacturing needs? Whether you're upgrading your equipment or investing in CNC for the first time, it’s crucial to consider factors that align with your goals.

In this guide, we will walk you through key insights to help you select the right CNC machine. You’ll understand how to evaluate your production needs, machine features, supplier support, and long-term costs to make a well-informed decision.

One of the first considerations when purchasing a CNC machine is the material compatibility. Different CNC machines are designed to handle different materials, such as wood, metals (aluminum, steel), plastics, or composites. Each material has specific machining requirements in terms of cutting speed, tooling, and spindle power.

For example, wood and plastic are softer materials that require lower spindle power, and machines like CNC routers may suffice for these. However, materials like steel or titanium require CNC machines with stronger spindles, higher power, and better rigidity. If you're planning to work with a variety of materials, look for a versatile machine that can handle multiple materials with different requirements.

Tip: If you're just starting and working primarily with softer materials like wood, a CNC router or mill would be a good fit. However, as your production needs grow or diversify, ensure the machine can be upgraded or adapted to handle harder materials like metals.

Your production volume will play a key role in determining the type of CNC machine you need. If you are producing a high volume of parts in a short time frame, you’ll need a machine that offers both speed and reliability. Machines with higher automation capabilities, such as multi-axis CNC machines or those with automatic tool changers, can handle repetitive tasks more efficiently.

For lower-volume, custom, or prototype work, a less automated machine may be sufficient. However, remember that the cost per part might be higher for smaller runs, and production speeds might not meet the demand if you scale up in the future.

The precision and accuracy of the CNC machine are critical factors, especially in industries that require high tolerances, such as aerospace, automotive, or medical equipment. If your parts require extremely tight tolerances (e.g., microns), you’ll need to invest in a machine that can consistently maintain those standards.

Understanding the part tolerances you require is essential to avoid over-specifying accuracy, which could lead to unnecessary costs. Machines advertised as having high accuracy may not always perform consistently in real-world conditions, especially if they are not set up and calibrated properly.

Part size is another key consideration when selecting a CNC machine. Larger parts, such as automotive components or aerospace structures, require machines with larger work envelopes. If you plan on manufacturing larger parts, ensure that the machine has enough space to accommodate the size of your workpieces, with additional space for fixturing and material handling.

Additionally, consider your future production plans. Even if your current needs are small, purchasing a machine that can handle larger parts might be a wise investment if you anticipate growing production volumes or working with larger materials in the future.

The spindle of a CNC machine is its heart—responsible for rotating the cutting tool and enabling the material to be shaped. When selecting a CNC machine, ensure that the spindle's horsepower (HP) and RPM match the requirements of the materials you plan to cut.

Harder materials like steel or titanium demand a more powerful spindle to maintain cutting speed and efficiency, while softer materials like wood and plastics require less power. Consider both the spindle’s maximum speed (RPM) and the torque it can provide. High-speed spindles with low torque are typically ideal for softer materials, while lower RPM spindles with higher torque are better for tougher materials.

The machine's size and footprint determine the amount of space it will occupy in your shop. CNC machines come in various sizes, so it’s essential to choose one that fits within your available workspace. Be sure to account for not just the machine's dimensions but also the clearance needed for material handling, maintenance access, and safety considerations.

A larger machine with a more significant work envelope is suitable for manufacturing larger parts, but it will require more floor space and potentially a higher power supply. Ensure you have enough room not only for the machine itself but also for associated equipment such as material storage, workholding devices, and tool changers.

In addition to the initial purchase price of the CNC machine, tooling costs can represent a significant part of the total investment. Tooling includes the cutting tools, fixtures, and other accessories that the machine requires to perform its tasks. While basic tooling may be included with the machine, ongoing replacement and maintenance costs are necessary to keep the machine performing at its best.

Maintenance costs should also be factored into your budget. Some machines require more frequent maintenance due to the complexity of their parts or the intensity of their use. Regular maintenance can prevent costly breakdowns and extend the lifespan of your machine.

| Tooling Cost Consideration | Impact |

|---|---|

| Initial Tooling Costs | May be included but often high, especially for specialized materials. |

| Ongoing Maintenance | Can be costly, depending on machine type and usage. Regular tool replacement is required. |

| Tooling Lifespan | Varies based on material and usage; affects overall production costs. |

As CNC technology has advanced, machines have become more automated. Some CNC machines offer automation features like tool changers, automatic part loaders, and multi-axis capabilities that enhance efficiency. These features can significantly reduce the need for operator intervention, increasing production speed and reducing human error.

For high-volume production, automation can be a game-changer, as it allows machines to run for extended periods without supervision. However, these machines often come at a higher upfront cost. If your production volumes are lower or you’re working on custom jobs, a less automated machine might be sufficient.

The supplier you choose for your CNC machine is just as important as the machine itself. Research potential suppliers thoroughly, paying attention to customer reviews, testimonials, and user forums. A supplier’s reputation is a good indicator of the quality of their machines and after-sales support.

Look for suppliers with a proven track record of reliability, quality, and customer satisfaction. A reputable supplier will not only provide a high-quality product but will also be there for you if issues arise after the sale.

Having a strong post-purchase support system is crucial when buying a CNC machine. A reliable warranty ensures you're covered for any potential defects or issues with the machine. Some suppliers offer extended warranties or service agreements, providing peace of mind for long-term ownership.

Ensure that the supplier offers reliable technical support, either through phone, email, or on-site service. Fast and efficient support can minimize downtime and keep your operations running smoothly.

CNC machines are complex and often require specialized knowledge to operate effectively. Many suppliers offer training programs that ensure your team can use the machine safely and efficiently. Whether on-site or through online courses, proper training is essential to avoid mistakes, improve safety, and optimize machine performance.

The supplier should also provide setup assistance to help you get the machine up and running. Proper installation and calibration are critical for ensuring the machine operates as expected.

While the initial price of the CNC machine is important, the total cost of ownership encompasses far more than just the purchase price. You must consider ongoing costs such as tooling, maintenance, energy usage, and possible downtime. A machine that seems inexpensive upfront may end up costing more over time due to high tooling or maintenance costs.

One of the most important factors to consider when purchasing a CNC machine is its return on investment (ROI). Will the machine increase your production capacity, improve part quality, or reduce labor costs? A good ROI ensures that the machine will pay for itself over time by increasing productivity or reducing costs in your business.

Tip: Evaluate the expected ROI based on your production needs, part quality, and business goals. A high-quality machine can significantly boost your business's efficiency and profitability in the long run.

CNC machines can be a significant investment, and not all businesses have the capital to pay for them upfront. Many suppliers offer financing options such as leasing or loans, which can help you manage the cost over time. Explore different financing options and choose the one that best suits your business's financial situation.

Routine maintenance is key to keeping your CNC machine running smoothly and preventing expensive breakdowns. Different machines have different maintenance requirements, but all need regular inspections, lubrication, and occasional adjustments to ensure optimal performance.

Ensure that the CNC machine supplier provides easy access to spare parts. Machines from reputable suppliers usually offer a reliable parts supply, which minimizes downtime. Spare parts should be readily available and reasonably priced.

CNC machines are an investment that should last for many years. A more expensive machine may offer better durability and require less maintenance over its lifespan. Investing in a durable machine upfront can save you money in the long run by reducing the need for frequent repairs and replacements.

The CNC machine’s control system plays a vital role in converting design data into machine instructions. Ensure that the machine’s control system is compatible with your existing CAD/CAM software. Compatibility with widely used software can streamline your operations and reduce the learning curve.

If your team is new to CNC machines, look for a machine with an easy-to-use interface. Some machines offer conversational programming, which simplifies the setup and operation of the machine, making it easier for beginners to learn.

Choosing the right CNC machine requires thoughtful planning and evaluation. By understanding your production needs and evaluating machine specifications, you can select the best fit. Considering the total cost of ownership will ensure your decision aligns with your business goals.

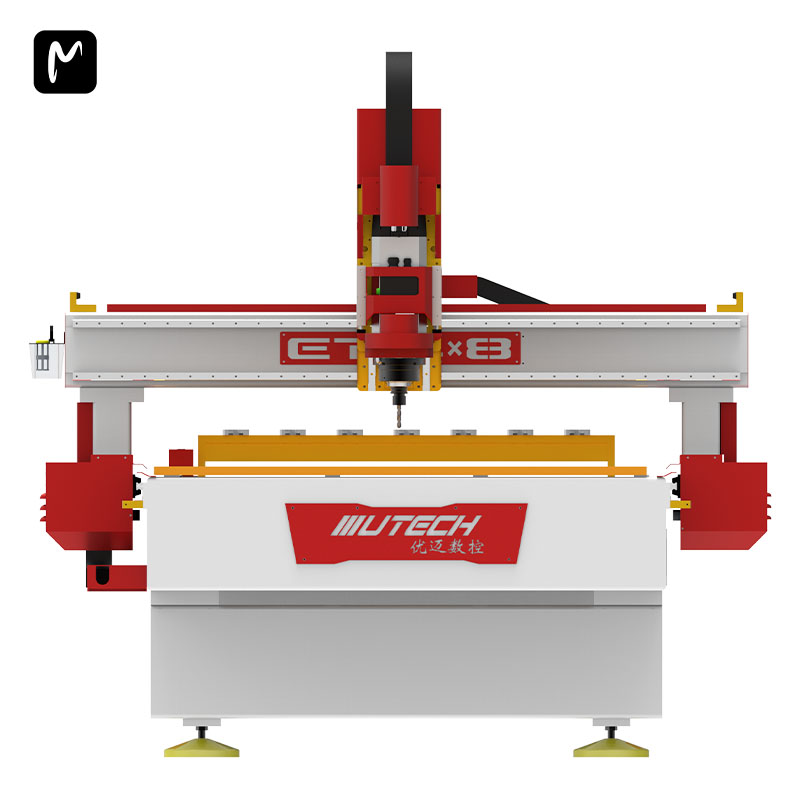

Take the time to assess all factors carefully to make an investment that enhances your efficiency and profitability. Products from UTECH provide advanced features and exceptional service, offering great value for your business’s CNC needs.

A: A CNC machine is a Computer Numerical Control machine that automates the control of tools like drills, mills, and lathes. It allows for precise and repeatable manufacturing of parts.

A: To choose the right CNC machine, consider your production needs, material types, required precision, and available floor space. Evaluate your budget and future scalability.

A: Spindle power determines how well a CNC machine can cut through different materials. The right spindle horsepower and RPM ensure the machine performs efficiently for your material requirements.

A: Costs include the initial purchase price, tooling, maintenance, energy consumption, and potential downtime. Tooling and regular maintenance are significant ongoing expenses.

A: Research the supplier’s reputation through reviews, customer references, and industry feedback. Ensure they offer good post-purchase support, warranties, and training.