- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Working Area: | |

|---|---|

| Table Structure: | |

| Driving System: | |

| Spindle Motor: | |

| Dust collector: | |

| Availability: | |

SESAME S2

UTECH

Sign Board Making Machine Cnc Machine for Sign Making

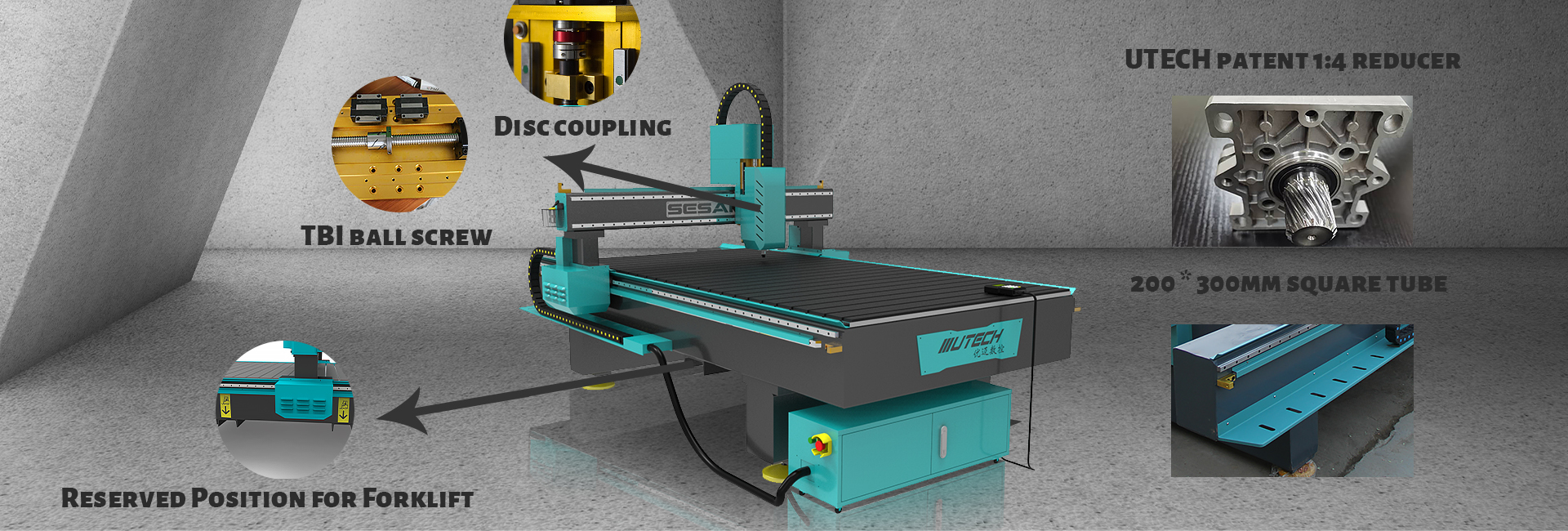

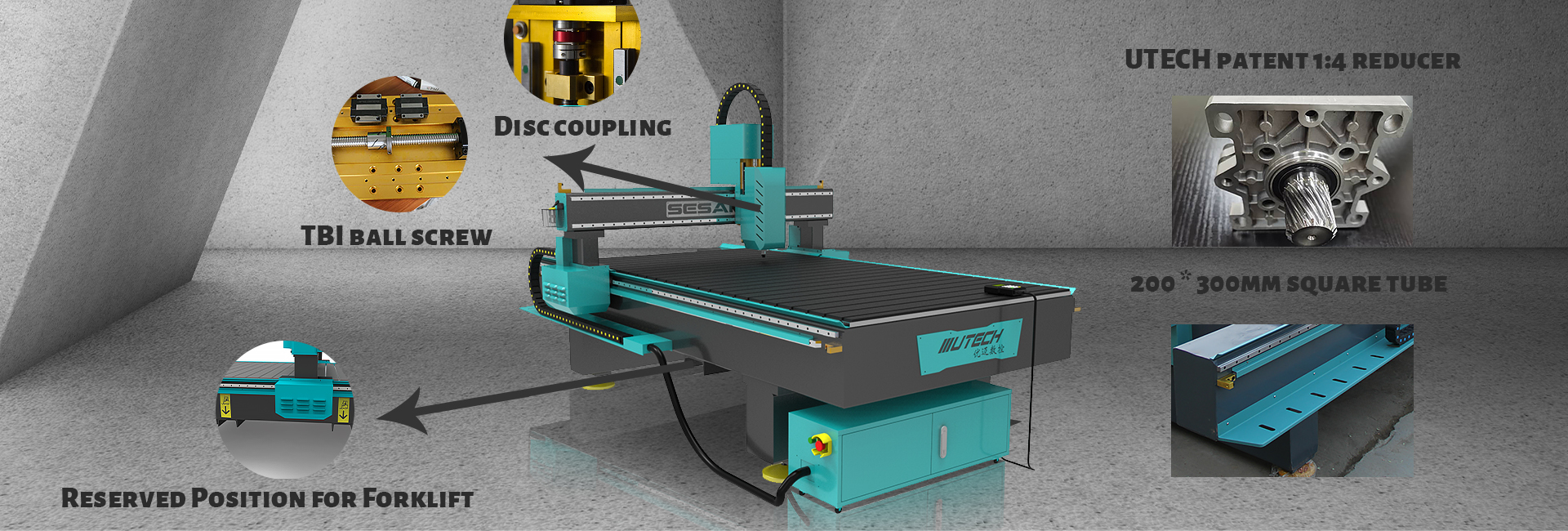

The UTECH SESAME series CNC engraving machine is specifically designed for the advertising signage processing industry, offering high stability, high precision, and cost-effectiveness, making it an ideal production equipment for businesses. The machine features a 200×300mm heavy-duty thickened square tube welded bed, a 150×200mm gantry frame, and cast iron columns, ensuring robustness and durability while maintaining stable, vibration-free operation even during high-speed cutting. All three axes are equipped with industrial-grade high-precision linear guides, resulting in lower rolling resistance, stronger motor torque output, and smoother processing. Dust covers are also included to effectively extend the life of the guides. The machine utilizes a high-quality reducer structure, achieving low backlash, low noise, and precise transmission, avoiding the problems of loosening and short lifespan associated with traditional gearboxes and synchronous belts. Precision assembly by the UTECH professional team ensures a repeatability accuracy of ±0.01mm, guaranteeing higher cutting quality and better detail in the processing of acrylic illuminated letters, PVC letters, KT boards, two-color boards, and other advertising materials. It is a reliable choice for advertising signage manufacturers to improve efficiency and quality.

Sign Board Making Machine Cnc Machine for Sign Making

The UTECH SESAME series CNC engraving machine is specifically designed for the advertising signage processing industry, offering high stability, high precision, and cost-effectiveness, making it an ideal production equipment for businesses. The machine features a 200×300mm heavy-duty thickened square tube welded bed, a 150×200mm gantry frame, and cast iron columns, ensuring robustness and durability while maintaining stable, vibration-free operation even during high-speed cutting. All three axes are equipped with industrial-grade high-precision linear guides, resulting in lower rolling resistance, stronger motor torque output, and smoother processing. Dust covers are also included to effectively extend the life of the guides. The machine utilizes a high-quality reducer structure, achieving low backlash, low noise, and precise transmission, avoiding the problems of loosening and short lifespan associated with traditional gearboxes and synchronous belts. Precision assembly by the UTECH professional team ensures a repeatability accuracy of ±0.01mm, guaranteeing higher cutting quality and better detail in the processing of acrylic illuminated letters, PVC letters, KT boards, two-color boards, and other advertising materials. It is a reliable choice for advertising signage manufacturers to improve efficiency and quality.

Machine Parameters

Descriptions | Parameters | |||

Model | SESAME S2 1325 | SESAME S2 1530 | SESAME S2 2030 | SESAME S2 2040 |

Working area | 1300*2500mm | 1500*3000mm | 2000*3000mm | 2000*4000mm |

Accuracy | 0.05mm | |||

Table Surface | Vacuum&T-slot table | |||

Frame | Square pipe welding bed structure 200*300mm+150*200mmgantry | |||

X, Y Structure | 1.25M Gear and rack transmission, Taiwan Linear Rail | |||

Z Structure | Taiwan TBI Ball Screw, Taiwan Linear Rail | |||

Spindle Power | 4.5kw air cooled spindle+ER25 cutter | |||

Spindle Speed | 0-24000RPM | |||

Drive Motors | JMC stepper motor and driver | |||

Working Voltage | AC 220/380V | |||

Command Language | G Code | |||

Operating System | HD100 handle controller (DSP or Mach3 optional) | |||

Computer Interface | Ethernet (or USB) | |||

Inverter | Best | |||

Software | Vectric Aspire/Type 3 /Artcam /Ucancam/JDPaint | |||

Machine Parameters

Descriptions | Parameters | |||

Model | SESAME S2 1325 | SESAME S2 1530 | SESAME S2 2030 | SESAME S2 2040 |

Working area | 1300*2500mm | 1500*3000mm | 2000*3000mm | 2000*4000mm |

Accuracy | 0.05mm | |||

Table Surface | Vacuum&T-slot table | |||

Frame | Square pipe welding bed structure 200*300mm+150*200mmgantry | |||

X, Y Structure | 1.25M Gear and rack transmission, Taiwan Linear Rail | |||

Z Structure | Taiwan TBI Ball Screw, Taiwan Linear Rail | |||

Spindle Power | 4.5kw air cooled spindle+ER25 cutter | |||

Spindle Speed | 0-24000RPM | |||

Drive Motors | JMC stepper motor and driver | |||

Working Voltage | AC 220/380V | |||

Command Language | G Code | |||

Operating System | HD100 handle controller (DSP or Mach3 optional) | |||

Computer Interface | Ethernet (or USB) | |||

Inverter | Best | |||

Software | Vectric Aspire/Type 3 /Artcam /Ucancam/JDPaint | |||

Application

1.Advertising industry: Acrylic, two-color board, PVC, ABS board, aluminum board, two-color portrait, three-dimensional advertising, all kinds of standard, badge, coordinate card, copper, font, font, all kinds of logos, trademarks, etc.

2.Woodworking industry: furniture decoration, musical instrument manufacturing, wooden crafts, solid wood furniture, office furniture, custom furniture, MDF paint-free doors, composite doors, cabinets, wardrobes, window doors, bedside tables, etc.

3.Decoration industry: art models, murals, screens, reliefs, ornament processing, gift packaging, wave boards, electrical countertops, sporting goods and other wood products.

Application

1.Advertising industry: Acrylic, two-color board, PVC, ABS board, aluminum board, two-color portrait, three-dimensional advertising, all kinds of standard, badge, coordinate card, copper, font, font, all kinds of logos, trademarks, etc.

2.Woodworking industry: furniture decoration, musical instrument manufacturing, wooden crafts, solid wood furniture, office furniture, custom furniture, MDF paint-free doors, composite doors, cabinets, wardrobes, window doors, bedside tables, etc.

3.Decoration industry: art models, murals, screens, reliefs, ornament processing, gift packaging, wave boards, electrical countertops, sporting goods and other wood products.

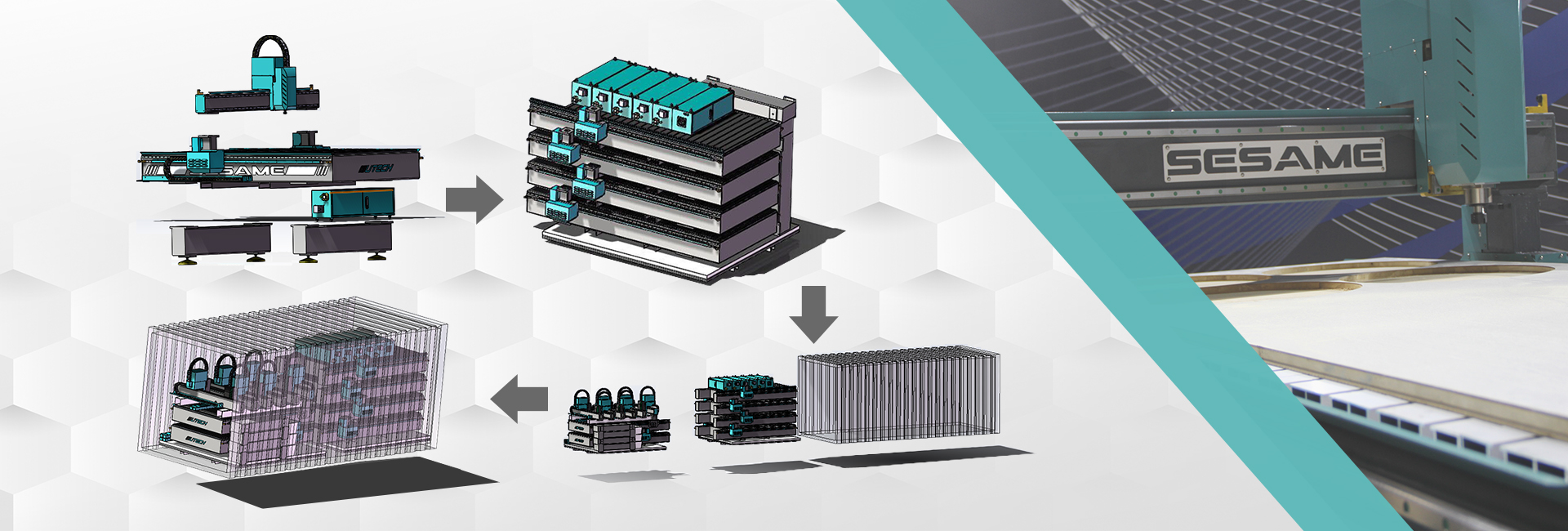

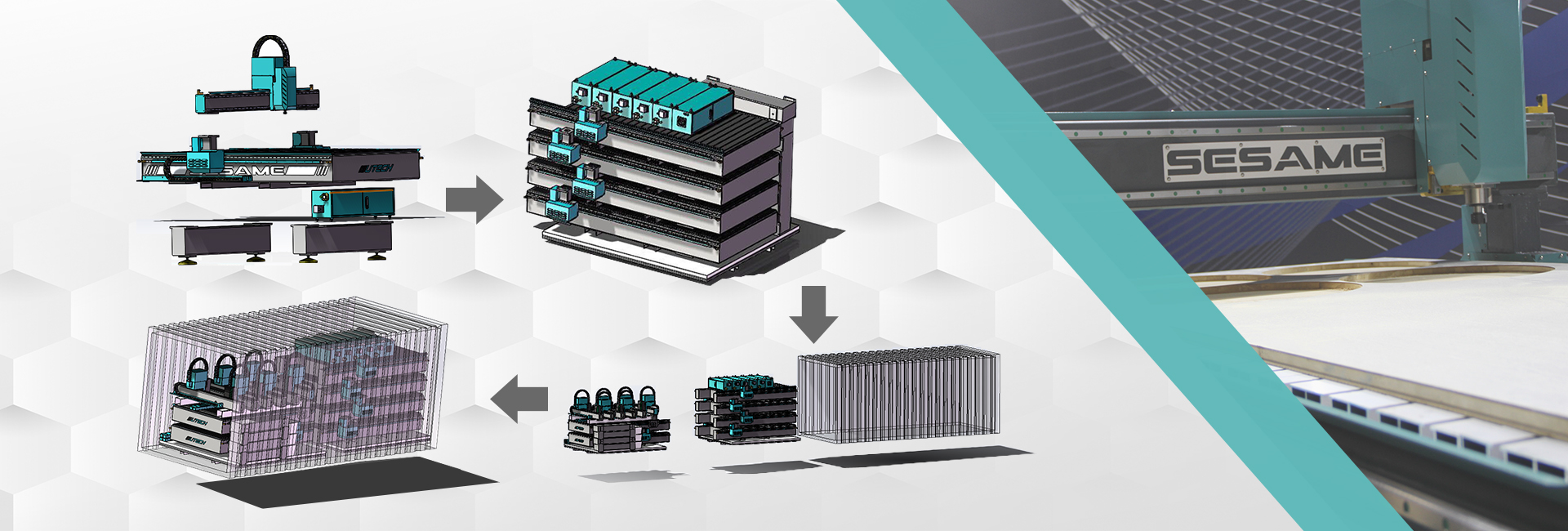

Packing:

1/ If the machine is delivered via LCL, then would be packed with wrapping film, EPE foam, and a standard export plywood box.

2/ If machine delivery via FCL, then don't need a wood box, would be packed with wrapping film and EPE foam.

Shipping:

We support machine delivery via express, air transportation, land transportation, and sea transportation.

1/ Such as some small machine, Mini CNC Router or Small CO2 Laser Machine and Fiber Laser Marking Machine, usually delivered via express and air transportation.

2/ If you wanna us to help you deliver to a domestic warehouse or Russia, Kazakhstan, etc, usually delivered via land transportation.

3/ Large machines or some countries where shipping is more convenient, usually suggest choosing sea transportation.

You can choose any way you'd prefer, we also will give you some proper suggestions.

Packing:

1/ If the machine is delivered via LCL, then would be packed with wrapping film, EPE foam, and a standard export plywood box.

2/ If machine delivery via FCL, then don't need a wood box, would be packed with wrapping film and EPE foam.

Shipping:

We support machine delivery via express, air transportation, land transportation, and sea transportation.

1/ Such as some small machine, Mini CNC Router or Small CO2 Laser Machine and Fiber Laser Marking Machine, usually delivered via express and air transportation.

2/ If you wanna us to help you deliver to a domestic warehouse or Russia, Kazakhstan, etc, usually delivered via land transportation.

3/ Large machines or some countries where shipping is more convenient, usually suggest choosing sea transportation.

You can choose any way you'd prefer, we also will give you some proper suggestions.

FAQ

1. How to guarantee the product to me? Is the purchase procedure complicated?

After you purchase CNC Engraving and Cutting Machine, we will keep in touch with you. The specific delivery process is in accordance with international trade practices, you can rest assured. If there is any doubt on some matters, the two sides can negotiate and deal with it.

2. What should I do if the product is found defective upon receipt of the goods?

Under normal circumstances, we will make strict inspection and test before the product leaves the factory. Video inspection is allowed if conditions permit. If you have time, you can come to our factory for on-site inspection. We will mail the missing parts and components in time.

3. How is the product packaged?

Product packaging is divided into three layers. The outer box is made of wood craft box.In the middle, the machine is covered with foam to protect it from vibration. The inner layer is waterproof and moisture-proof with thickened plastic bags.

4. Why can you trust us?

Our products are of high quality. We import important parts and components from Taiwan, Japan, etc., and have a series of relevant certificates as the basic guarantee. The whole process of assembly and processing has a full range of monitoring.In addition, the after-sales treatment is quite rigorous, and we will have technical staff to answer questions online in time.

5. What kind of factory is it?

Our company belongs to typical industrial and trading a shape, a statement that it is very

important, because the factory can control the machine quality, and trade departments can correct fully introduce to the buyer, integrating two department, not only guarantee the product quality, and can do real-time docking factories and sales staff, saving problem to deal with the wait time for you.

FAQ

1. How to guarantee the product to me? Is the purchase procedure complicated?

After you purchase CNC Engraving and Cutting Machine, we will keep in touch with you. The specific delivery process is in accordance with international trade practices, you can rest assured. If there is any doubt on some matters, the two sides can negotiate and deal with it.

2. What should I do if the product is found defective upon receipt of the goods?

Under normal circumstances, we will make strict inspection and test before the product leaves the factory. Video inspection is allowed if conditions permit. If you have time, you can come to our factory for on-site inspection. We will mail the missing parts and components in time.

3. How is the product packaged?

Product packaging is divided into three layers. The outer box is made of wood craft box.In the middle, the machine is covered with foam to protect it from vibration. The inner layer is waterproof and moisture-proof with thickened plastic bags.

4. Why can you trust us?

Our products are of high quality. We import important parts and components from Taiwan, Japan, etc., and have a series of relevant certificates as the basic guarantee. The whole process of assembly and processing has a full range of monitoring.In addition, the after-sales treatment is quite rigorous, and we will have technical staff to answer questions online in time.

5. What kind of factory is it?

Our company belongs to typical industrial and trading a shape, a statement that it is very

important, because the factory can control the machine quality, and trade departments can correct fully introduce to the buyer, integrating two department, not only guarantee the product quality, and can do real-time docking factories and sales staff, saving problem to deal with the wait time for you.