- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

High quality affordable CNC Router machine for woodworking 1325

Before confirming the production order, we will provide the rendering picture and 360-degree panoramic video, so that customers can fully understand the style and structure of the machine, so as to ensure that the actual machine meets the requirements of customers, so as to avoid the discrepancy between the real object and customers' imagination caused by various communication deviations.

UTECH technical support is designed to help you make the most of the machine. A variety of technical files and installation videos will be placed in the U disk and shipped with the machine. Our technical experts can provide online remote support and training, and contact UTECH technical support experts in real-time for remote diagnosis. Door-to-door service is also available.

| Size: | |

|---|---|

| Spindle Motor: | |

| XYZ Transmission: | |

| Drive&Motor: | |

| X,Y,Z Guide Rail: | |

| Availability: | |

UT-1325

UTECH

20211325

China Supplier Wood Cnc Router with Automatic Lubrication

Descriptions | Parameters | |||

Model | SESAME S2 1325 | SESAME S2 1530 | SESAME S2 2030 | SESAME S2 2040 |

Working area | 1300*2500mm | 1500*3000mm | 2000*3000mm | 2000*4000mm |

Accuracy | ±0.05mm | |||

Table Surface | T-slot table (vacuum table is optional) | |||

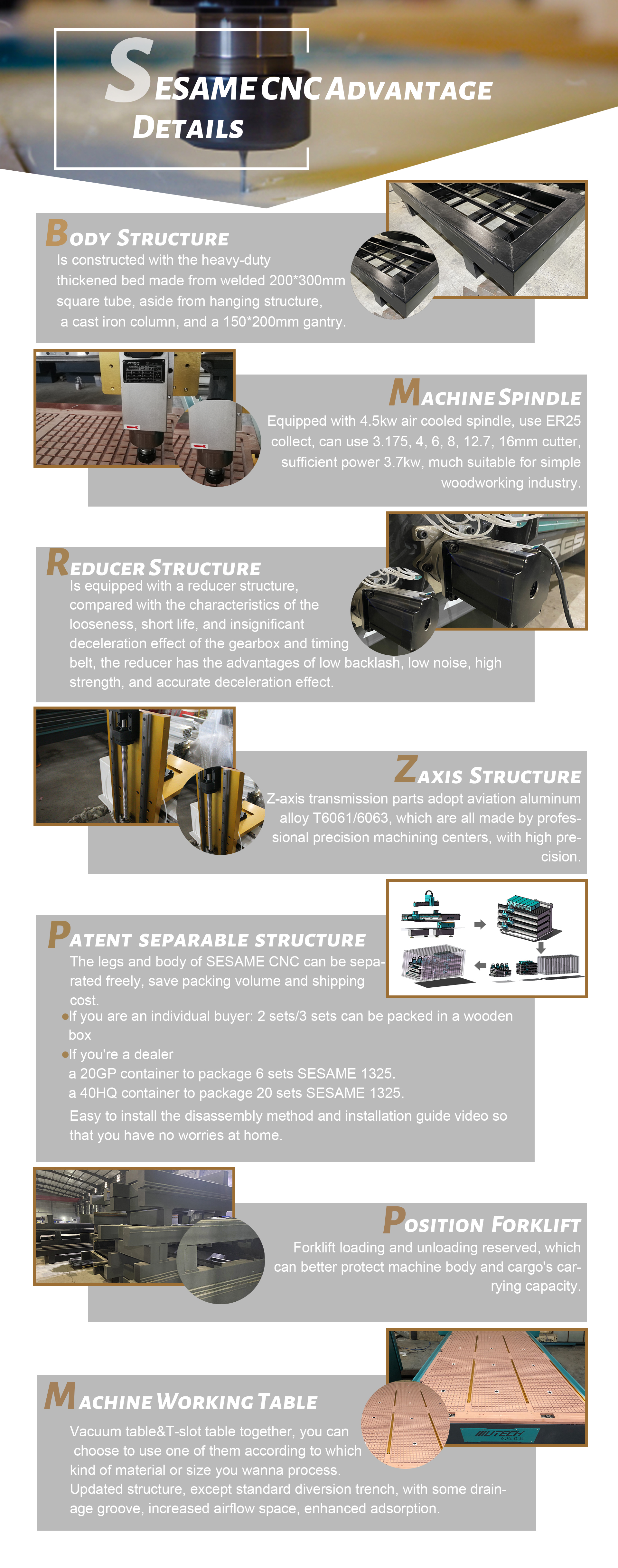

Frame | Square pipe welding bed structure 200*300mm+150*200mmgantry | |||

X, Y Structure | 1.25M Gear and rack transmission, Taiwan Linear Rail | |||

Z Structure | Taiwan TBI Ball Screw, Taiwan Linear Rail | |||

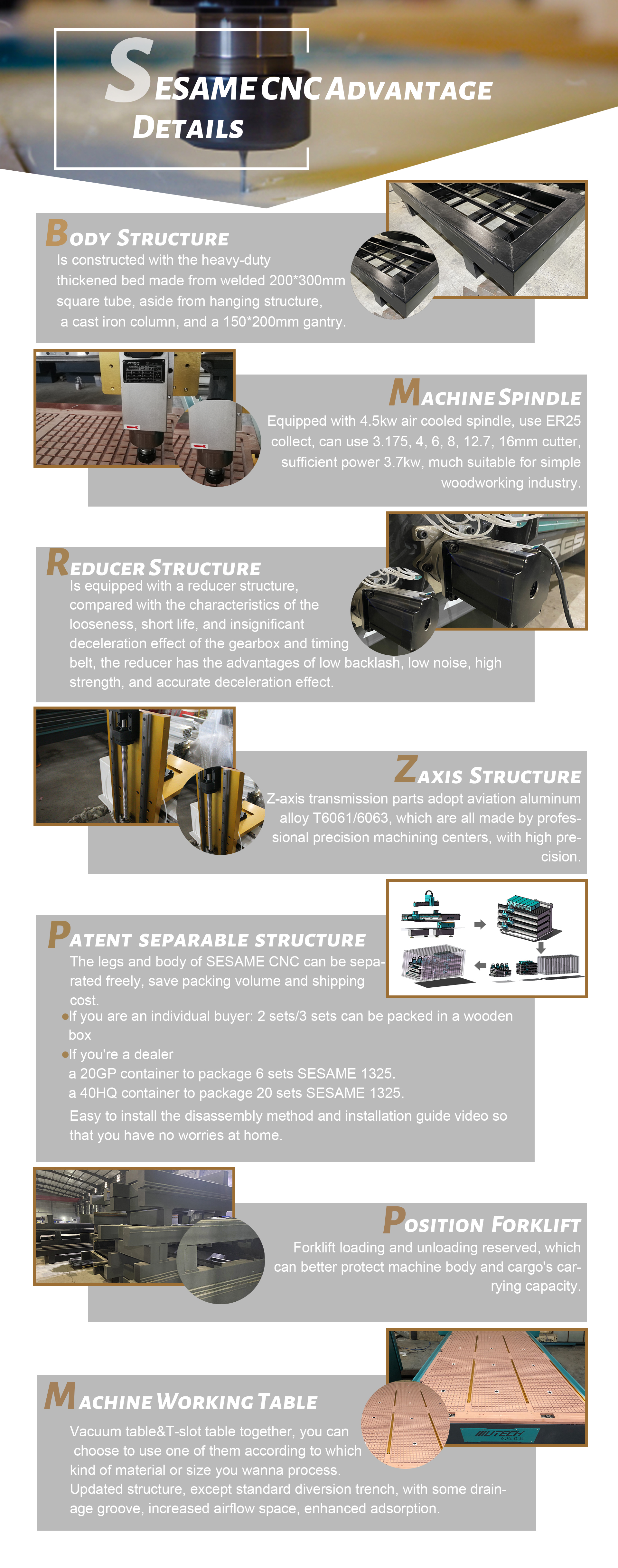

Spindle Power | 4.5kw air cooled spindle+ER25 cutter | |||

Spindle Speed | 0-24000RPM | |||

Drive Motors | JMC stepper motor and driver | |||

Working Voltage | AC 220/380V | |||

Command Language | G Code | |||

Operating System | HD100 handle controller (DSP or Mach3 optional) | |||

Computer Interface | Ethernet (or USB) | |||

Inverter | Best | |||

Software | Vectric Aspire/Type 3 /Artcam /Ucancam/JDPaint | |||

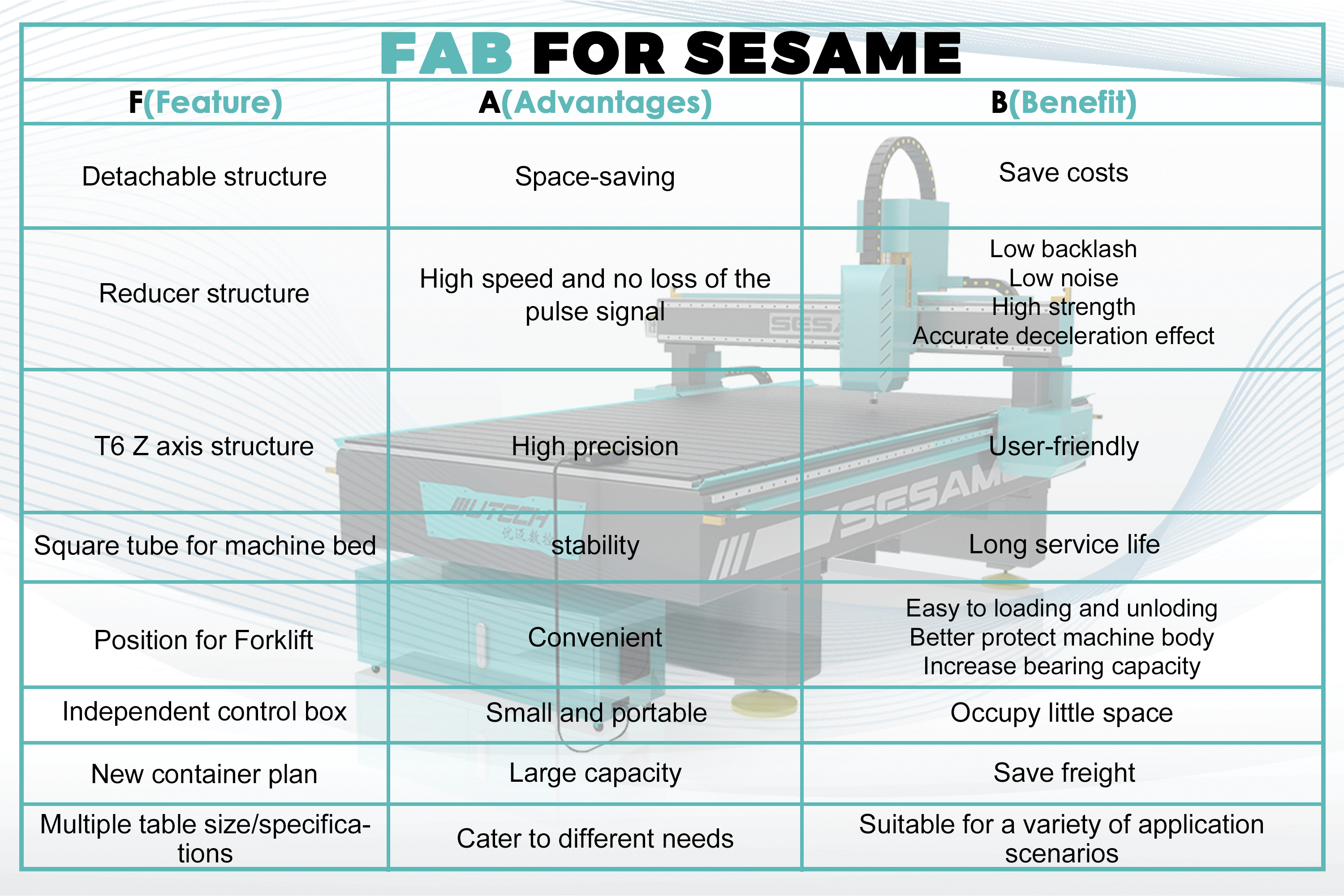

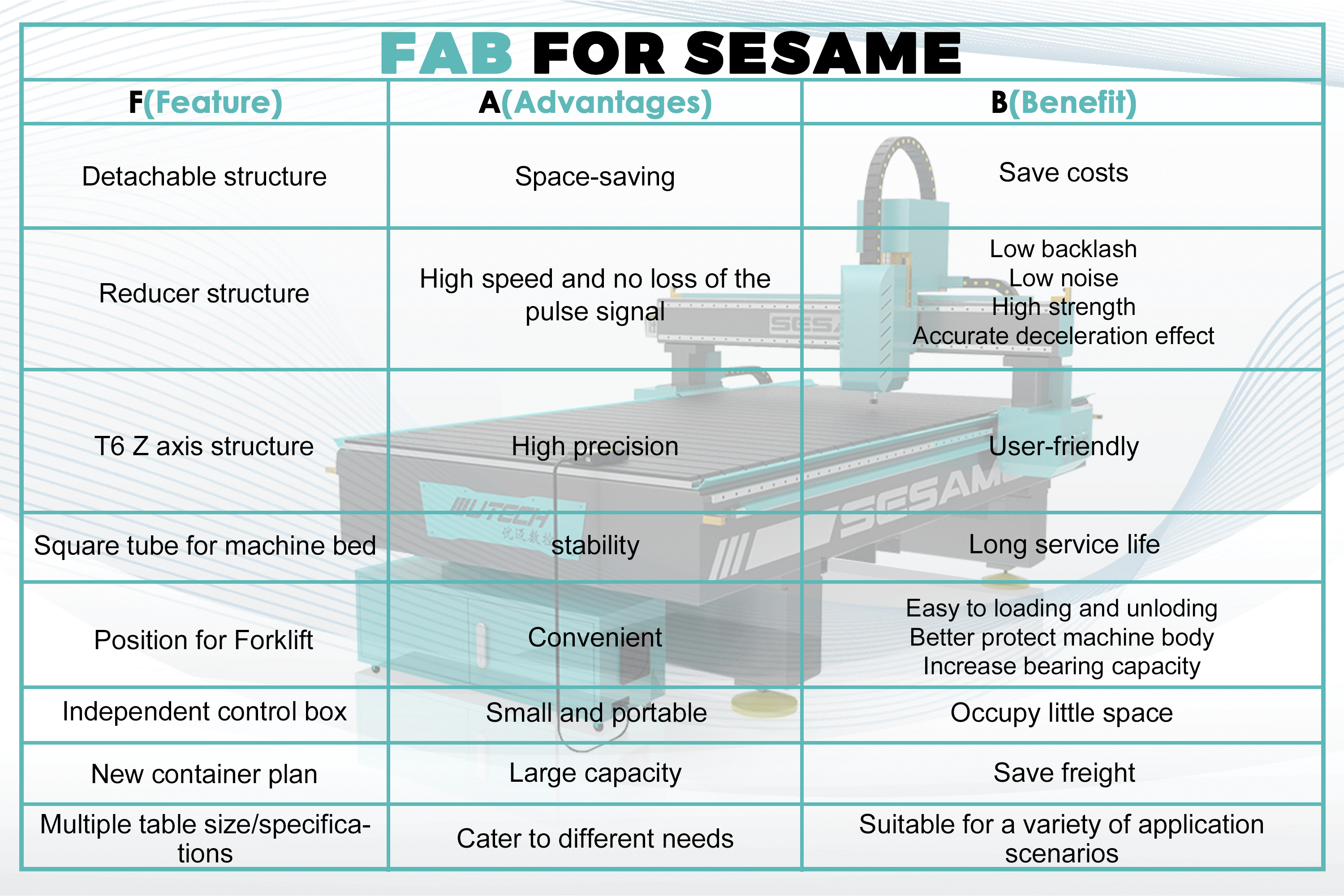

SESAME Cnc Router's standard parts:

1. Leg Removable Frame

2. 4.5kw air cooled spindle+ER25 cutter, cutting thick materials, also is easy (optional)

3. Machine Base Frame

4. Anodized Aluminum Spindle Fixing plate (Z axis)

5. Dust cover for the guide rail and the helical rack gear

6. TBI High-Precision Ball-screw Transmission (Taiwan)

7. Patent design 1:4 gear reducer + Stepper 450B driving motor

8. Hiwin/PMI square rail& High quality helical rack pinion

9. CNC Tool Sensor

SESAME Cnc Router's optional parts:

1. Mach3/4/DSP controller

2. Rotary(length&diameter could be customized)

3. Automatic lubricator

4. Dust collector

5. Oil mist lubrication pump

6. T-slot table

China Supplier Wood Cnc Router with Automatic Lubrication

Descriptions | Parameters | |||

Model | SESAME S2 1325 | SESAME S2 1530 | SESAME S2 2030 | SESAME S2 2040 |

Working area | 1300*2500mm | 1500*3000mm | 2000*3000mm | 2000*4000mm |

Accuracy | ±0.05mm | |||

Table Surface | T-slot table (vacuum table is optional) | |||

Frame | Square pipe welding bed structure 200*300mm+150*200mmgantry | |||

X, Y Structure | 1.25M Gear and rack transmission, Taiwan Linear Rail | |||

Z Structure | Taiwan TBI Ball Screw, Taiwan Linear Rail | |||

Spindle Power | 4.5kw air cooled spindle+ER25 cutter | |||

Spindle Speed | 0-24000RPM | |||

Drive Motors | JMC stepper motor and driver | |||

Working Voltage | AC 220/380V | |||

Command Language | G Code | |||

Operating System | HD100 handle controller (DSP or Mach3 optional) | |||

Computer Interface | Ethernet (or USB) | |||

Inverter | Best | |||

Software | Vectric Aspire/Type 3 /Artcam /Ucancam/JDPaint | |||

SESAME Cnc Router's standard parts:

1. Leg Removable Frame

2. 4.5kw air cooled spindle+ER25 cutter, cutting thick materials, also is easy (optional)

3. Machine Base Frame

4. Anodized Aluminum Spindle Fixing plate (Z axis)

5. Dust cover for the guide rail and the helical rack gear

6. TBI High-Precision Ball-screw Transmission (Taiwan)

7. Patent design 1:4 gear reducer + Stepper 450B driving motor

8. Hiwin/PMI square rail& High quality helical rack pinion

9. CNC Tool Sensor

SESAME Cnc Router's optional parts:

1. Mach3/4/DSP controller

2. Rotary(length&diameter could be customized)

3. Automatic lubricator

4. Dust collector

5. Oil mist lubrication pump

6. T-slot table

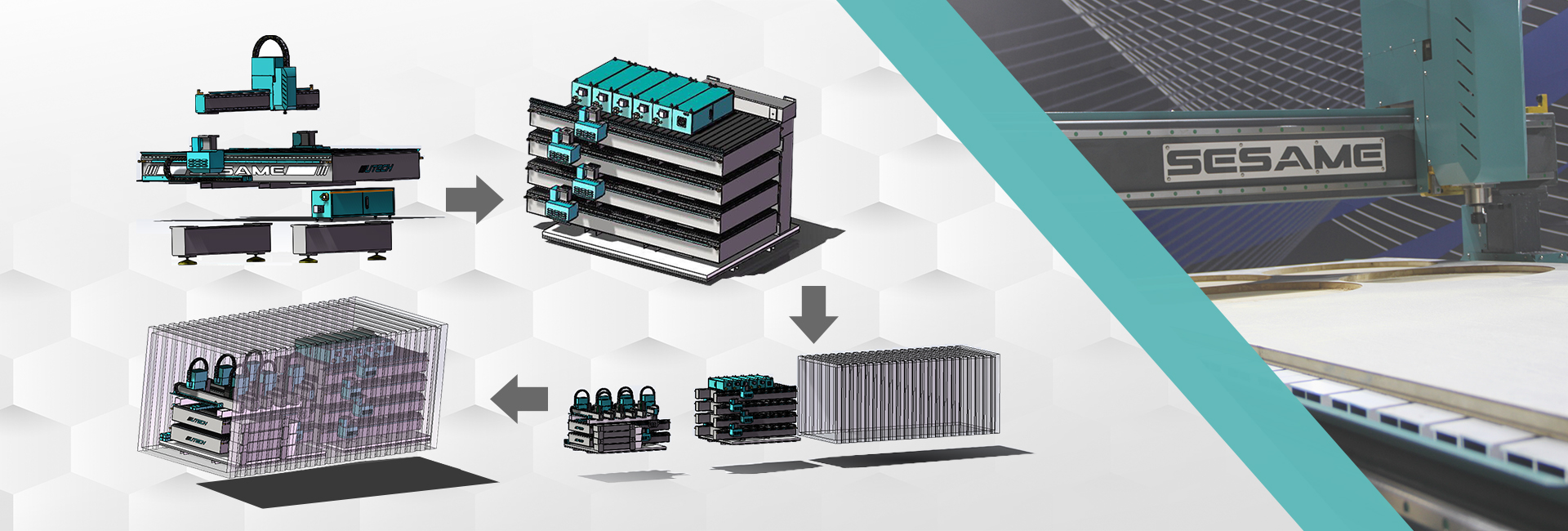

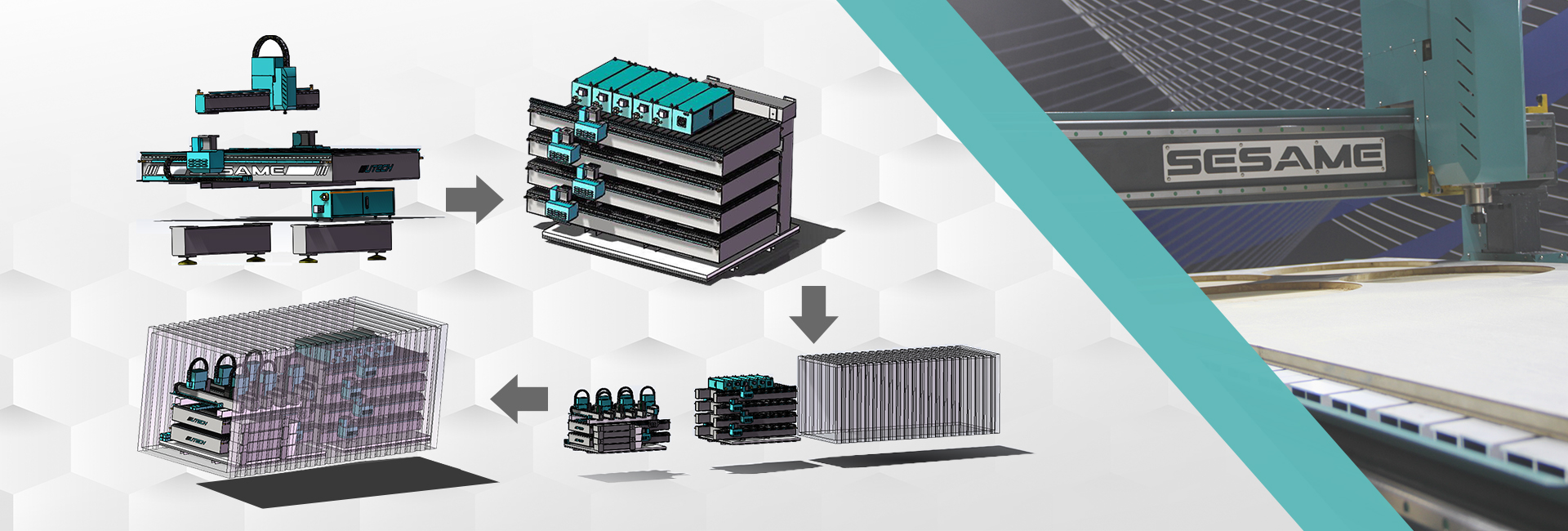

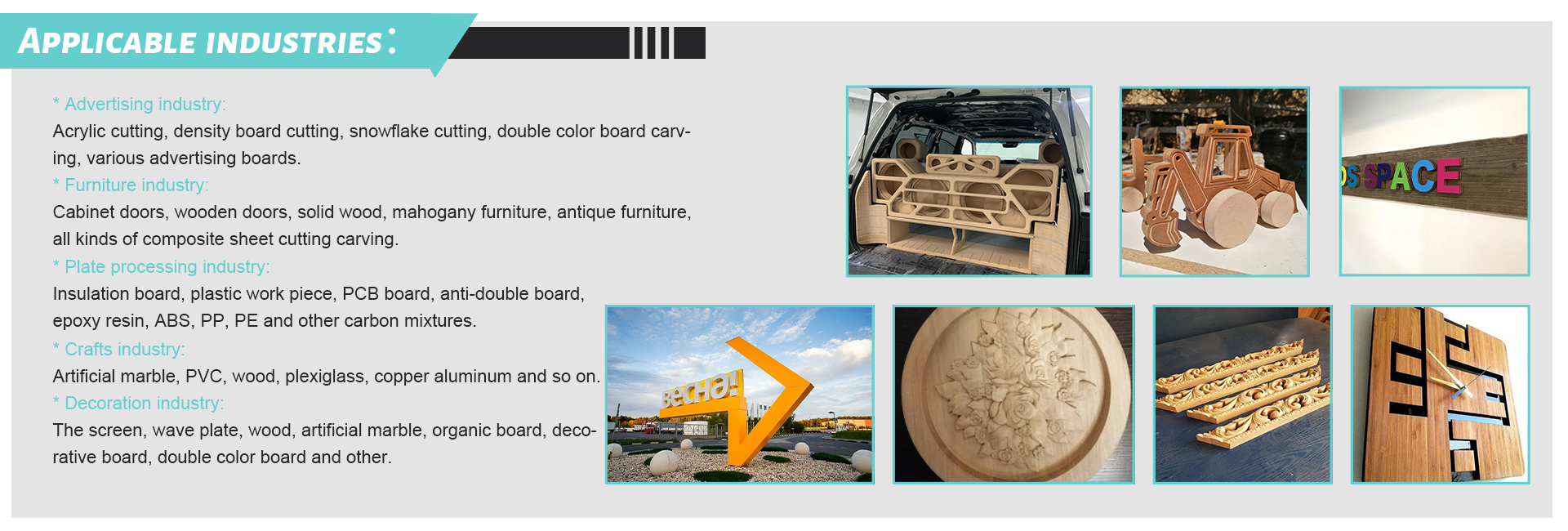

Patent separable structure

SESAME series have distinctive designs for the international market, highly visual impact. We have already owned the patent of appearance design and another multiple from China.

Save the shipping costs.

Very convenient for loading and unloading goods.

The whole machine assembly process is upgraded.

Machine legs and machine body could be separated freely, could save some space and shipping freight, before package, the customer could choose to dismantle or not, also easy to install, if dismantle, we'll take video for showing how to dismantle and assemble.

A 20GP container could pack 6 sets of SESAME 1325.

A 40GP container could pack 14 sets of SESAME 1325.

Patent separable structure

SESAME series have distinctive designs for the international market, highly visual impact. We have already owned the patent of appearance design and another multiple from China.

Save the shipping costs.

Very convenient for loading and unloading goods.

The whole machine assembly process is upgraded.

Machine legs and machine body could be separated freely, could save some space and shipping freight, before package, the customer could choose to dismantle or not, also easy to install, if dismantle, we'll take video for showing how to dismantle and assemble.

A 20GP container could pack 6 sets of SESAME 1325.

A 40GP container could pack 14 sets of SESAME 1325.

1. Machine bed

Machine bed with 200 * 300mm square tube welded together, compared to ordinary machines, we use the square tube model can better reflect the stability of the equipment.

2. Reserved Position for Forklift

The bed welding process increases the reserved forklift, highlights two major advantages: First, increase the strength of the bed itself; Second, it`s more convenient for customers to load or unload the equipment.

3. Transmission stand column

Transmission stand column, we adopt a high precision machining process, ensure the accuracy of accessories. Like, insert cavity position, assembly surface.

4. SESAME machine head

First, For the choice of the handpiece, we choose T6061/6063 aviation aluminum alloy as the base material. Through the precision processing of the CNC Processing Center, we finished our finished parts. Second, the high requirement assembly process ensures the precision of the product.

5. Unpacking saves transportation costs+Patent design transmission structure.

6. Optimize the design structure to facilitate the customer fork handling equipment, reserved for forklift special seats.

7. SESAME adopts a portable optimized design small separate control cabinet.

1. Machine bed

Machine bed with 200 * 300mm square tube welded together, compared to ordinary machines, we use the square tube model can better reflect the stability of the equipment.

2. Reserved Position for Forklift

The bed welding process increases the reserved forklift, highlights two major advantages: First, increase the strength of the bed itself; Second, it`s more convenient for customers to load or unload the equipment.

3. Transmission stand column

Transmission stand column, we adopt a high precision machining process, ensure the accuracy of accessories. Like, insert cavity position, assembly surface.

4. SESAME machine head

First, For the choice of the handpiece, we choose T6061/6063 aviation aluminum alloy as the base material. Through the precision processing of the CNC Processing Center, we finished our finished parts. Second, the high requirement assembly process ensures the precision of the product.

5. Unpacking saves transportation costs+Patent design transmission structure.

6. Optimize the design structure to facilitate the customer fork handling equipment, reserved for forklift special seats.

7. SESAME adopts a portable optimized design small separate control cabinet.

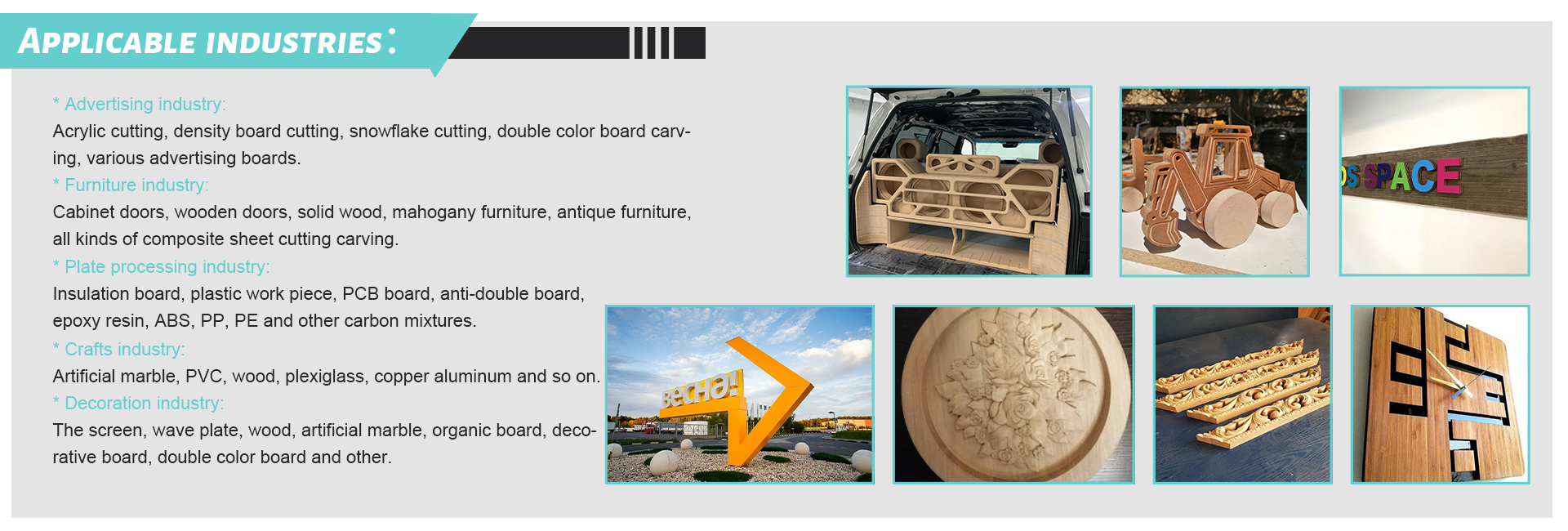

1. Advertising industry

Acrylic cutting, density board cutting, snowflake cutting, double color board carving, various advertising boards.

2. Furniture industry

Cabinet doors, wooden doors, solid wood, mahogany furniture, antique furniture, all kinds of composite sheet cutting carving.

3. Plate processing industry

Insulation board, plastic work piece, PCB board, anti-double board, epoxy resin, ABS, PP, PE and other carbon mixtures.

4. Crafts industry

Artificial marble, PVC, wood, plexiglass, copper aluminum and so on

1. Advertising industry

Acrylic cutting, density board cutting, snowflake cutting, double color board carving, various advertising boards.

2. Furniture industry

Cabinet doors, wooden doors, solid wood, mahogany furniture, antique furniture, all kinds of composite sheet cutting carving.

3. Plate processing industry

Insulation board, plastic work piece, PCB board, anti-double board, epoxy resin, ABS, PP, PE and other carbon mixtures.

4. Crafts industry

Artificial marble, PVC, wood, plexiglass, copper aluminum and so on

About UTECH – A Professional CNC Solutions Provider from China

Founded in 2014 and headquartered in Jinan, China, Shandong U-May Cnc Technology Co., Ltd. is a professional manufacturer dedicated to the research, development, production, and sales of advanced CNC equipment. Leveraging modern production facilities and a strong engineering team, UTECH provides global customers with one-stop CNC solutions, including CNC engraving machines, automatic tool changer CNC engraving machines, laser cutting machines, plasma cutting machines, and other customized automation equipment.

Driven by technology and innovation, every UTECH CNC machine is manufactured according to strict quality control standards—from mechanical design and precision assembly to software integration—ensuring high stability, high precision, and long service life. UTECH products are widely used in industries such as woodworking, advertising, metal processing, plastics, composite materials, and mold making, and have earned a strong reputation for reliability and high performance in the global market.

Adhering to the philosophy of "Focusing on Quality, Serving with Technology," UTECH continuously expands its international business, providing customized solutions and professional technical support to partners and customers in more than 100 countries and regions. Whether you are a small workshop or a large industrial manufacturer, UTECH is committed to helping your business achieve smarter and more efficient production.

7. After machine shipped, I'll prepare some documents, like B/L, Packing List, Commerical Invoice, Commerical Contract, CE certificate for helping you pick up your machine.

About UTECH – A Professional CNC Solutions Provider from China

Founded in 2014 and headquartered in Jinan, China, Shandong U-May Cnc Technology Co., Ltd. is a professional manufacturer dedicated to the research, development, production, and sales of advanced CNC equipment. Leveraging modern production facilities and a strong engineering team, UTECH provides global customers with one-stop CNC solutions, including CNC engraving machines, automatic tool changer CNC engraving machines, laser cutting machines, plasma cutting machines, and other customized automation equipment.

Driven by technology and innovation, every UTECH CNC machine is manufactured according to strict quality control standards—from mechanical design and precision assembly to software integration—ensuring high stability, high precision, and long service life. UTECH products are widely used in industries such as woodworking, advertising, metal processing, plastics, composite materials, and mold making, and have earned a strong reputation for reliability and high performance in the global market.

Adhering to the philosophy of "Focusing on Quality, Serving with Technology," UTECH continuously expands its international business, providing customized solutions and professional technical support to partners and customers in more than 100 countries and regions. Whether you are a small workshop or a large industrial manufacturer, UTECH is committed to helping your business achieve smarter and more efficient production.

7. After machine shipped, I'll prepare some documents, like B/L, Packing List, Commerical Invoice, Commerical Contract, CE certificate for helping you pick up your machine.