- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: UTECH CNC Publish Time: 2025-10-31 Origin: UTECH CNC

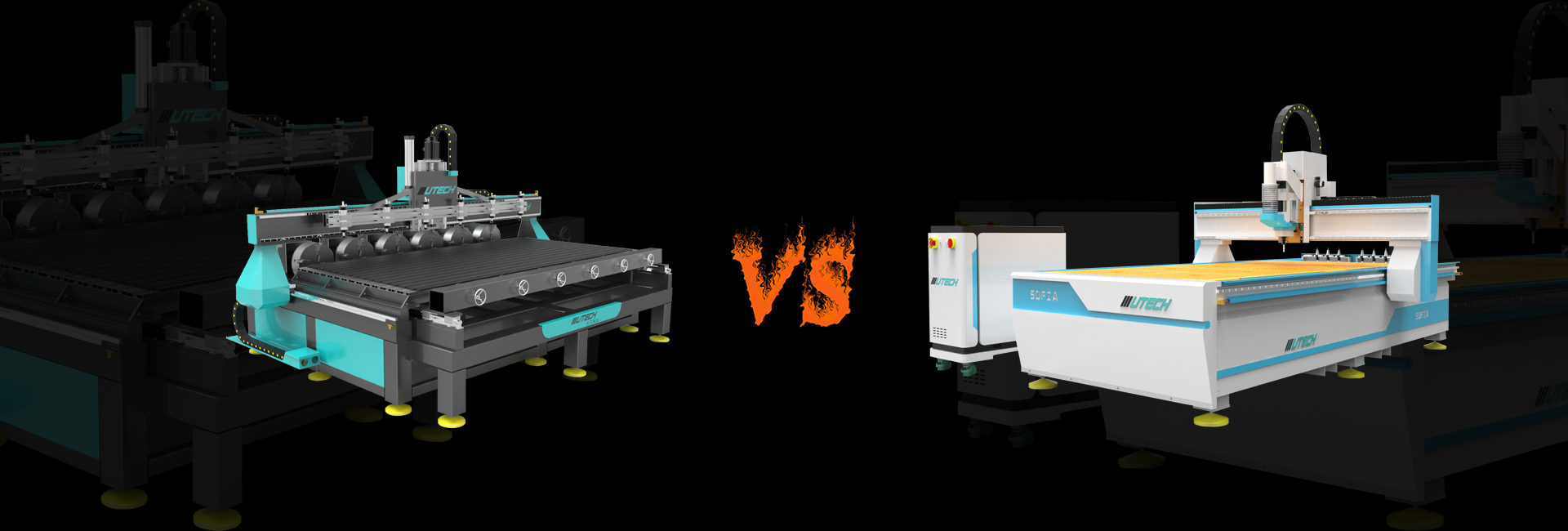

CNC engraving machines have become indispensable tools in modern woodworking, furniture production, and industrial manufacturing. Whether you are creating intricate patterns, cutting solid wood panels, or engraving custom designs, choosing the right CNC woodworking machine tool directly impacts your efficiency and precision. Among the many types of CNC engraving machines, the multi-spindle CNC router and the ATC CNC router are two common choices. Both are designed to simplify woodworking, engraving, and cutting processes, but they differ significantly in structure, functionality, and cost. Understanding these differences helps users select the most suitable CNC machine tool based on their production needs.

1. Tool Changing System: Manual vs. Automatic

2. Functions and Machining Capabilities of Multi-Axis CNC Router and ATC CNC Router

3. Target Users and Application Scenarios of Multi-spindle CNC Router and ATC CNC Router

4. Cost and Investment Considerations for Multi-Axis CNC Router vs. ATC CNC Router

The most significant difference between multi-axis CNC engraving machines and ATC CNC engraving machines lies in their tool changing mechanisms.

Multi-axis CNC engraving machines reduce the user's purchase cost and achieve a degree of automatic tool changing, but the number of tools is limited—usually 3, 4, or a maximum of 8. Each spindle can be equipped with different tools, allowing the machine to perform multiple machining operations without manual tool changing. However, once these limited tools are used, subsequent changes require manual intervention.

In contrast, TC CNC engraving machines are equipped with independent tool magazines, which can be linear or rotary. Depending on the model and customer requirements, they can accommodate 4, 8, 10, 12, 16, or even more tools. When changing tools, the machine head automatically moves to the tool magazine, selects the required tool, and continues engraving without interruption. This achieves fast and seamless tool changing, improving work efficiency and reducing downtime—ideal for factories pursuing high-volume, high-precision production.

When it comes to functionality, both machines have clear positioning.

The multi-spindle CNC router is capable of performing basic woodworking tasks such as engraving, cutting, and drilling. It’s a great option for medium-scale workshops where operators need to process multiple workpieces simultaneously or switch between a few different tools. This makes it perfect for applications like cabinet doors, wooden furniture panels, and decorative engraving.

On the other hand, the ATC CNC router supports a broader range of machining operations including boring, drilling, side milling, slot cutting, chamfering, and even 3D relief engraving. It’s designed to handle complex projects that require multiple tool types, ensuring high precision and consistent results. In high-end manufacturing industries such as custom furniture production, mold making, and aerospace component fabrication, the ATC CNC router’s versatility is unmatched.

Multi-spindle CNC Router machines are primarily aimed at customers requiring reliable performance at a reasonable price. For example, in woodworking shops or door and window processing plants, a configuration with 2-3 or 3-4 spindles can easily complete daily production tasks. It is ideal for users who want to increase productivity but do not want to invest in high-end automation equipment.

Conversely, ATC CNC Router machines are aimed at high-end users with advanced machining needs. They are suitable for producing parts or artworks with complex contours, multi-layered structures, or intricate designs. When precision, speed, and flexibility are primary considerations, an automatic tool changer (ATC) CNC engraving machine is undoubtedly the best choice.

In terms of cost, multi-axis CNC engraving machines have lower entry-level prices and maintenance costs, making them ideal for startups or small workshops. However, due to their limited tool capacity and automation, they may not meet the needs of complex or high-volume production.

While automatic tool changer CNC engraving machines are more expensive, they offer a long-term return on investment by reducing labor, increasing efficiency, and improving machining accuracy. Automatic tool changer CNC engraving machines offer significant advantages for companies focused on scaling up production or processing multiple materials such as wood, acrylic, MDF, PVC, and aluminum composite panels.

Choosing between a multi-spindle CNC Router and an ATC CNC Router depends on your production needs and budget. If you need a cost-effective, stable, and reliable machine for simple cutting and engraving, a multi-axis model will be your ideal choice. However, if you require high precision, complex machining, and rapid tool changing, then an automatic tool-changing CNC engraving machine is undoubtedly the better choice.

UTECH CNC offers a full range of CNC solutions, covering three-axis and four-axis engraving machines, automatic tool-changing CNC engraving machines, and multi-head CNC engraving machines, designed to meet a variety of industrial needs. Whether you operate a small workshop or manage a large production line, our technical team will assist you in selecting the most suitable CNC engraving machine to improve your productivity and machining quality. Contact us for more information!