- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

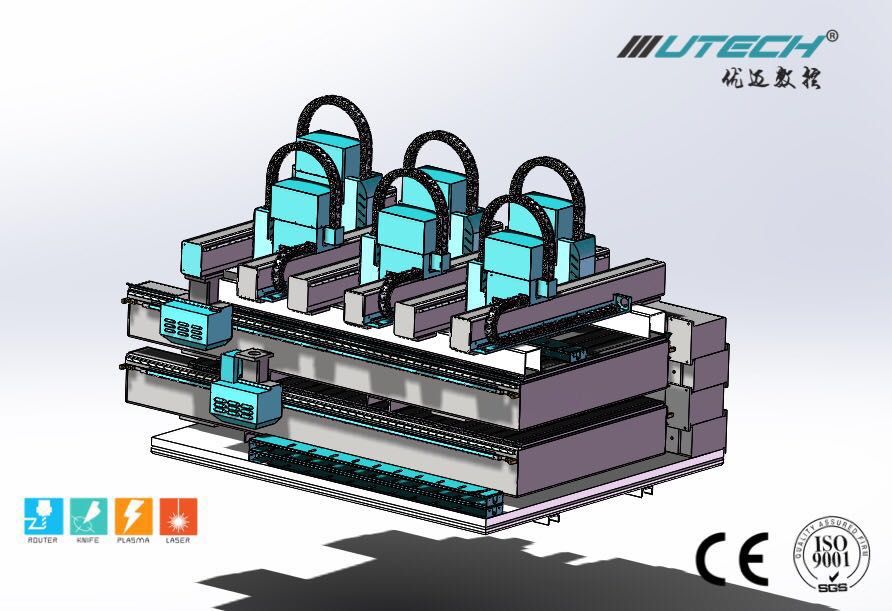

SESAME P1

UTECH

Product Description

1. Welded thick-walled steel structure, after special treatment, no distortion for the whole structure high precision, and long service life time.

2. Cutting system use Beijing Starfire system/ Start system/ FLMC-2300A or DSP system; Equipped with automatic height controller (THC controller), which can according to your material planeness, cutting head can automatically stable, and fast adjust.

3. Taiwan linear rail, ensure vertical section, more precision.

4. Suitable software: Artcam/ Fastcam/ Starfire etc.

5. FASTCAM programming software based on AutoCAD automatic programming and material system.

6. FASTCAM is designed for all kinds of NC cutter with cutting software, the software can help the user completing various complex parts drawing, programming, material, using convenient, also bring the obvious economic benefit.

7. If you cut thick material, according to actual use, we’ll add water tank for you for free, to absorbs a large amount of smoke generated during cutting.

8. Machine could be customized, whatever specifications, appearance, etc. Any request you’ve, could tell us directly.

Power source

Brand | Power | Recommended cutting thickness for carbon steel | Recommended cutting thickness for stainless steel |

| LGK 63A | 10mm | 5mm |

LGK 100A | 12mm | 6mm | |

LGK 120A | 15mm | 8mm | |

LGK 160A | 20mm | 10mm | |

LGK 200A | 25mm | 15mm | |

| 8mm | 3mm | |

Powermax 65A | 12mm | 5mm | |

Powermax 85A | 15mm | 6mm | |

Powermax 105A | 18mm | 10mm | |

Powermax 125A | 25mm | 16mm |

Parameter list

Model | SESAME P1 |

Working size | 1300mm*2500mm, 100mm stroke z-axis sliding table |

Cutting speed | 10-15m/min |

Transmission system | 1.25m rack, square 20 linear guide and slider |

Operating System | Starfire SF2100/DSP A12 control system |

Driver | JMC stepper motor and driver |

Plasma power supply | Huayuan/Hypertherm |

Cutting thickness | 0-30mm |

Cutting type | Plasma/oxy-acetylene or propane |

Input voltage | 3 phase,220v/380v±10% |

Mode of file transfer | USB Interface |

Water tank | Underlay stainless steel sink(absorb smoke and prevent burning) |

Table-board | sawtooth + square pipe, spacing is 70 mm |

Straight line positioning precision | ±0.2mm/10m |

Straight line repeat precision | ±0.3mm/10m |

Environmental temperature | -5~45°C |

Humidity | <90% No concreting |

Details

| Plasma cutting head Including control box for adjusting height, photoelectric switch and limit switch.

|

| Starfire control system+Shanghai HYD Arc voltage regulator Adjust the distance automatically as the different materials |

| Plamsa power supply Chinese Huayuan power supply/America Hypertherm power supply is optional |

| Gear+Taiwan HIWIN rail guide XY axis by gear rack transmission, HIWIN rail guide to make machine higher precision, faster cutting speed, more bettre cutting performance. |

| JMC Stepper driver |

| sawtooth + square pipe The table can bear 2000-2500kg without deformation. |

| Split structure Machine legs and machine body could be splitted freely, then could help you save much space and shipping freight. |

| Fastcam software FASTCAM help the user completing various complex parts drawing, programming, material, using convenient. |

| Water tank absorb smoke and prevent burning |

| Independent control cabinet |

Application Industry

It is widely used in the process of cutting metal plates in the machinery manufacturing industry, engineering industry and metal fabrication and can cut mild steel, stainless steel, aluminium, copper and many kinds of non-ferrous metal.

Characteristics

SESAME P1 plasma cutting machine continues the split design of SESAME S2 CNC ROUTER, save the shipping cost.

Machine legs and machine body could be separated freely, could save some space and shipping freight, before package, customer could choose dismantle or not, also easy to install, if dismantle, we'll take video for showing how to dismantle and assemble.

A 20GP container could pack six sets SESAME P1 1325.

Product Description

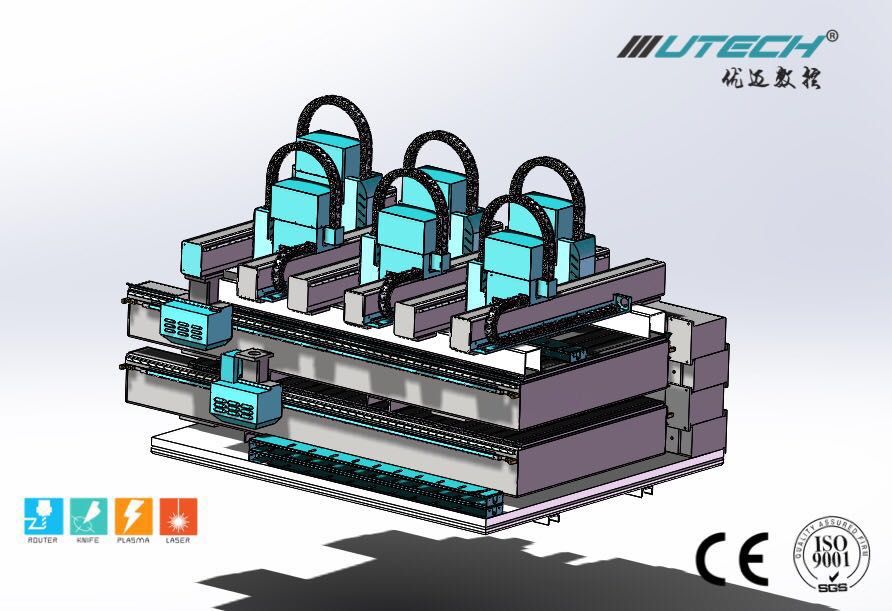

1. Welded thick-walled steel structure, after special treatment, no distortion for the whole structure high precision, and long service life time.

2. Cutting system use Beijing Starfire system/ Start system/ FLMC-2300A or DSP system; Equipped with automatic height controller (THC controller), which can according to your material planeness, cutting head can automatically stable, and fast adjust.

3. Taiwan linear rail, ensure vertical section, more precision.

4. Suitable software: Artcam/ Fastcam/ Starfire etc.

5. FASTCAM programming software based on AutoCAD automatic programming and material system.

6. FASTCAM is designed for all kinds of NC cutter with cutting software, the software can help the user completing various complex parts drawing, programming, material, using convenient, also bring the obvious economic benefit.

7. If you cut thick material, according to actual use, we’ll add water tank for you for free, to absorbs a large amount of smoke generated during cutting.

8. Machine could be customized, whatever specifications, appearance, etc. Any request you’ve, could tell us directly.

Power source

Brand | Power | Recommended cutting thickness for carbon steel | Recommended cutting thickness for stainless steel |

| LGK 63A | 10mm | 5mm |

LGK 100A | 12mm | 6mm | |

LGK 120A | 15mm | 8mm | |

LGK 160A | 20mm | 10mm | |

LGK 200A | 25mm | 15mm | |

| 8mm | 3mm | |

Powermax 65A | 12mm | 5mm | |

Powermax 85A | 15mm | 6mm | |

Powermax 105A | 18mm | 10mm | |

Powermax 125A | 25mm | 16mm |

Parameter list

Model | SESAME P1 |

Working size | 1300mm*2500mm, 100mm stroke z-axis sliding table |

Cutting speed | 10-15m/min |

Transmission system | 1.25m rack, square 20 linear guide and slider |

Operating System | Starfire SF2100/DSP A12 control system |

Driver | JMC stepper motor and driver |

Plasma power supply | Huayuan/Hypertherm |

Cutting thickness | 0-30mm |

Cutting type | Plasma/oxy-acetylene or propane |

Input voltage | 3 phase,220v/380v±10% |

Mode of file transfer | USB Interface |

Water tank | Underlay stainless steel sink(absorb smoke and prevent burning) |

Table-board | sawtooth + square pipe, spacing is 70 mm |

Straight line positioning precision | ±0.2mm/10m |

Straight line repeat precision | ±0.3mm/10m |

Environmental temperature | -5~45°C |

Humidity | <90% No concreting |

Details

| Plasma cutting head Including control box for adjusting height, photoelectric switch and limit switch.

|

| Starfire control system+Shanghai HYD Arc voltage regulator Adjust the distance automatically as the different materials |

| Plamsa power supply Chinese Huayuan power supply/America Hypertherm power supply is optional |

| Gear+Taiwan HIWIN rail guide XY axis by gear rack transmission, HIWIN rail guide to make machine higher precision, faster cutting speed, more bettre cutting performance. |

| JMC Stepper driver |

| sawtooth + square pipe The table can bear 2000-2500kg without deformation. |

| Split structure Machine legs and machine body could be splitted freely, then could help you save much space and shipping freight. |

| Fastcam software FASTCAM help the user completing various complex parts drawing, programming, material, using convenient. |

| Water tank absorb smoke and prevent burning |

| Independent control cabinet |

Application Industry

It is widely used in the process of cutting metal plates in the machinery manufacturing industry, engineering industry and metal fabrication and can cut mild steel, stainless steel, aluminium, copper and many kinds of non-ferrous metal.

Characteristics

SESAME P1 plasma cutting machine continues the split design of SESAME S2 CNC ROUTER, save the shipping cost.

Machine legs and machine body could be separated freely, could save some space and shipping freight, before package, customer could choose dismantle or not, also easy to install, if dismantle, we'll take video for showing how to dismantle and assemble.

A 20GP container could pack six sets SESAME P1 1325.