- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| 1300*2500*200mm: | |

|---|---|

| Workable size: | |

| Max Working Speed: | |

| Working Voltage: | |

| Command language: | |

| Operating system: | |

| X,Y,Z Guide Rail: | |

| Availability: | |

ATC-1325 4 axis

UTECH

1325 / 1530 Wood Furniture Woodworking 4 Axis Cnc Router Machine

The UTECH 4-axis ATC CNC engraving machine integrates high-speed automatic tool change, four-axis machining, and high-precision cutting, making it an ideal choice for professional woodworking and multi-material processing. It not only easily achieves complex curved surfaces, three-dimensional engraving, rotating workpieces, and multi-faceted processing, but also boasts an industrial-grade bed structure and high-precision transmission system, ensuring stability, durability, precision, and efficiency. Whether manufacturing furniture, handicrafts, or molds, this machine can significantly improve production efficiency, expand processing possibilities, and make your products more competitive in the market.

Machine Parameters:

Machine name | SOFIA 4th ATC CNC ROUTER |

Working table | Vaccum table and pump |

Workable size | 1500x3000x200mm |

Spindle motor | HQD 9kw air cooling spindle |

Control system | Weihong NK280B Controller |

X Y Z traveling Positioning accuracy | ±0.01 |

Max Working Speed | 24000mm/min |

Working Voltage | AC380V/50/60HZ |

Command language | G Code |

Operating system | YASKAWA servo motor |

X,Y,Z Guide Rail | Taiwan 25 Square Rail |

Computer Interface | USB |

Flash memory | 128M(U Disk) |

Collet | ISO30 |

Software | Type3/Wentai/Artcam |

1325 / 1530 Wood Furniture Woodworking 4 Axis Cnc Router Machine

The UTECH 4-axis ATC CNC engraving machine integrates high-speed automatic tool change, four-axis machining, and high-precision cutting, making it an ideal choice for professional woodworking and multi-material processing. It not only easily achieves complex curved surfaces, three-dimensional engraving, rotating workpieces, and multi-faceted processing, but also boasts an industrial-grade bed structure and high-precision transmission system, ensuring stability, durability, precision, and efficiency. Whether manufacturing furniture, handicrafts, or molds, this machine can significantly improve production efficiency, expand processing possibilities, and make your products more competitive in the market.

Machine Parameters:

Machine name | SOFIA 4th ATC CNC ROUTER |

Working table | Vaccum table and pump |

Workable size | 1500x3000x200mm |

Spindle motor | HQD 9kw air cooling spindle |

Control system | Weihong NK280B Controller |

X Y Z traveling Positioning accuracy | ±0.01 |

Max Working Speed | 24000mm/min |

Working Voltage | AC380V/50/60HZ |

Command language | G Code |

Operating system | YASKAWA servo motor |

X,Y,Z Guide Rail | Taiwan 25 Square Rail |

Computer Interface | USB |

Flash memory | 128M(U Disk) |

Collet | ISO30 |

Software | Type3/Wentai/Artcam |

9kw HQD ATC Air Cooled Spindle (HSD is optional)

9kw HQD ATC Air Cooled Spindle (HSD is optional)

High precision 9kw air cooling ATC spindle motor, after twice dynamic balance precision testing, can ensure the machining accuracy. Is equipped with an ISO30 tool holder and ER32 collect, programmable speeds of up to 24,000 RPM.

Automatic Tool Calibrater

The equipment with the tool calibrater can automatically set the offset value of the tool to the workpiece coordinate system after the tool setting, so that the workpiece coordinate system can be automatically established. In this way, the setting of the workpiece coordinate value can be easily realized. It can be said that the use of the tool setting instrument not only saves time, but also improves efficiency.

Independent Vertical Control Cabinet

Generally, machines equipped with industrial control systems such as ATC will use this independent vertical control cabinet, which is located on the left side of the machine, and the rotary axis is located on the right side of the machine, which is easy to operate. The interior can also be equipped with brackets for placing monitors and computer cabinets, and customers can use personal desktop computers at will.

It contains all the electronic components related to the machine, and is marked with the label of each cable, which is convenient for inspection and maintenance.

Linear automatic tool changer

The linear tool magazine can be placed under the gantry or behind the machine. The linear tool change usually could be support 4-10 pcs tool holder, with ISO 30 tool holder.

The following is the general process of tool change:

Tool change command> Confirm tool magazine retract> Reach tool change position 1> Tool Holder Lauch> Confirm tool holder push inposition> Loose tool holder> Loose tool holder confirmation signal> Reach tool change position 2> Clamp tool holder> Clamp tool confirmation signal> Tool holder retraction >Confirm tool holder retracted in place>Reached tool holder z height>Tool change completed

Machine Body

The Frame is the backbone of a CNC router machine, The SOFIA ATC frame adapts wall steel square tube welded together, precision machined and stress relieved so that the foundation remains true and steady over the operational life of the machine. solid and not deformed. The lathe bed is processed by industrial welding, quenching, and tempering and then machined by the machining center. The professional strengthening rib structure (sturdy bed welding process) ensures the bearing capacity and stability of the bed, ensuring the rigidity of the bed and Geometric accuracy; After high-temperature tempering treatment to ensure the best strength and rigidity side arranged structure, heavy column, etc. Compared to ordinary machines, it has a better stability.

Positioning Cylinder

For the standard 1325, the positioning cylinders are usually distributed in 2 on the X-axis and 3 on the Y-axis. These pneumatic devices form an L-shaped right angle. Function: Position the plate to be processed, reduce the time of manual positioning of the plate, and improve the efficiency of plate feeding. After installing the positioning cylinder, it is possible to ensure that each sheet is placed in the same position, without repeating the definition of the workpiece origin to ensure the positioning accuracy, which is simple to operate and saves time. The main point is safety performance. The positioning of the cylinder is also controlled by the control system's program. It has a cross-border protection device. When the positioning shaft of the cylinder extends, the machine automatically stops working to prevent the spindle tool from cutting the cylinder or the cylinder shaft from damaging the tool. , Can avoid unnecessary losses in a limited way.

Side 4th Rotary Axis

Adding a 4th rotary axis on the machine can not only realize the processing of flat workpieces, but also the processing of 3Dl workpieces and irregular workpieces.

You can choose the proper rotary's diameter and length according to your materials. It's mainly be used for processing some round or square materials.

SHIMPO Reducer

UTECH equipment is equipped with standard reducer structure---patented step reducer/Japan SHIMPO reducer 1:5/1:10. Compared with the reduction gear and the structure inside the gear box, the belt of the timing belt has a certain tension and is easy to loosen. It is often necessary to change the belt. There is also a gear box for the machine to decelerate. When the machine needs to decelerate and stop, the gear box has no effect. Obviously, and due to the use of timing belts, great inertia is easy to slip and overtravel.

The reducer has the characteristics of low backlash, low noise, high strength, and accurate deceleration effect.

Transmission

Transmission

UTECH ATC CNC Series Rack adopts high-precision 1.5M helical gear rack, which is complementary with the professional motor and professional deceleration device, which runs smoothly, high speed, high precision and low noise. Adapt PMI 25 Linear guide+Flange slider+precision 1.5M helical rack transmission structures can ensure that Running stably and reliably, working life is long, the machine can keep working for a long time.

Weihong NK280B Controller

NK280B is widely used in CNC engraving and milling machines/engraving machines. It is one of the representatives of Weihong's highly reliable and cost-effective motion control system; supports 4-axis linkage; supports Yaskawa M-II and Weizhi servo bus absolute value; serial Communication; I/O can be expanded with an 8-inch LCD display, embedded platform, and customers can carry out secondary development of the process.

Z axis Fixing Plate

Anodized Aviation Aluminum Spindle mounting plate The spindle is fixed on the high-quality aviation aluminum T6061/6063 plate, and it is Anodized Aluminum processing, the plate is machined with a high precision CNC machining center. Second, the high requirement assembly process ensures the precision of the product.

Z-axis adopts TBI High-Precision Ball-screw Transmission.

9kw HQD ATC Air Cooled Spindle (HSD is optional)

9kw HQD ATC Air Cooled Spindle (HSD is optional)

High precision 9kw air cooling ATC spindle motor, after twice dynamic balance precision testing, can ensure the machining accuracy. Is equipped with an ISO30 tool holder and ER32 collect, programmable speeds of up to 24,000 RPM.

Automatic Tool Calibrater

The equipment with the tool calibrater can automatically set the offset value of the tool to the workpiece coordinate system after the tool setting, so that the workpiece coordinate system can be automatically established. In this way, the setting of the workpiece coordinate value can be easily realized. It can be said that the use of the tool setting instrument not only saves time, but also improves efficiency.

Independent Vertical Control Cabinet

Generally, machines equipped with industrial control systems such as ATC will use this independent vertical control cabinet, which is located on the left side of the machine, and the rotary axis is located on the right side of the machine, which is easy to operate. The interior can also be equipped with brackets for placing monitors and computer cabinets, and customers can use personal desktop computers at will.

It contains all the electronic components related to the machine, and is marked with the label of each cable, which is convenient for inspection and maintenance.

Linear automatic tool changer

The linear tool magazine can be placed under the gantry or behind the machine. The linear tool change usually could be support 4-10 pcs tool holder, with ISO 30 tool holder.

The following is the general process of tool change:

Tool change command> Confirm tool magazine retract> Reach tool change position 1> Tool Holder Lauch> Confirm tool holder push inposition> Loose tool holder> Loose tool holder confirmation signal> Reach tool change position 2> Clamp tool holder> Clamp tool confirmation signal> Tool holder retraction >Confirm tool holder retracted in place>Reached tool holder z height>Tool change completed

Machine Body

The Frame is the backbone of a CNC router machine, The SOFIA ATC frame adapts wall steel square tube welded together, precision machined and stress relieved so that the foundation remains true and steady over the operational life of the machine. solid and not deformed. The lathe bed is processed by industrial welding, quenching, and tempering and then machined by the machining center. The professional strengthening rib structure (sturdy bed welding process) ensures the bearing capacity and stability of the bed, ensuring the rigidity of the bed and Geometric accuracy; After high-temperature tempering treatment to ensure the best strength and rigidity side arranged structure, heavy column, etc. Compared to ordinary machines, it has a better stability.

Positioning Cylinder

For the standard 1325, the positioning cylinders are usually distributed in 2 on the X-axis and 3 on the Y-axis. These pneumatic devices form an L-shaped right angle. Function: Position the plate to be processed, reduce the time of manual positioning of the plate, and improve the efficiency of plate feeding. After installing the positioning cylinder, it is possible to ensure that each sheet is placed in the same position, without repeating the definition of the workpiece origin to ensure the positioning accuracy, which is simple to operate and saves time. The main point is safety performance. The positioning of the cylinder is also controlled by the control system's program. It has a cross-border protection device. When the positioning shaft of the cylinder extends, the machine automatically stops working to prevent the spindle tool from cutting the cylinder or the cylinder shaft from damaging the tool. , Can avoid unnecessary losses in a limited way.

Side 4th Rotary Axis

Adding a 4th rotary axis on the machine can not only realize the processing of flat workpieces, but also the processing of 3Dl workpieces and irregular workpieces.

You can choose the proper rotary's diameter and length according to your materials. It's mainly be used for processing some round or square materials.

SHIMPO Reducer

UTECH equipment is equipped with standard reducer structure---patented step reducer/Japan SHIMPO reducer 1:5/1:10. Compared with the reduction gear and the structure inside the gear box, the belt of the timing belt has a certain tension and is easy to loosen. It is often necessary to change the belt. There is also a gear box for the machine to decelerate. When the machine needs to decelerate and stop, the gear box has no effect. Obviously, and due to the use of timing belts, great inertia is easy to slip and overtravel.

The reducer has the characteristics of low backlash, low noise, high strength, and accurate deceleration effect.

Transmission

Transmission

UTECH ATC CNC Series Rack adopts high-precision 1.5M helical gear rack, which is complementary with the professional motor and professional deceleration device, which runs smoothly, high speed, high precision and low noise. Adapt PMI 25 Linear guide+Flange slider+precision 1.5M helical rack transmission structures can ensure that Running stably and reliably, working life is long, the machine can keep working for a long time.

Weihong NK280B Controller

NK280B is widely used in CNC engraving and milling machines/engraving machines. It is one of the representatives of Weihong's highly reliable and cost-effective motion control system; supports 4-axis linkage; supports Yaskawa M-II and Weizhi servo bus absolute value; serial Communication; I/O can be expanded with an 8-inch LCD display, embedded platform, and customers can carry out secondary development of the process.

Z axis Fixing Plate

Anodized Aviation Aluminum Spindle mounting plate The spindle is fixed on the high-quality aviation aluminum T6061/6063 plate, and it is Anodized Aluminum processing, the plate is machined with a high precision CNC machining center. Second, the high requirement assembly process ensures the precision of the product.

Z-axis adopts TBI High-Precision Ball-screw Transmission.

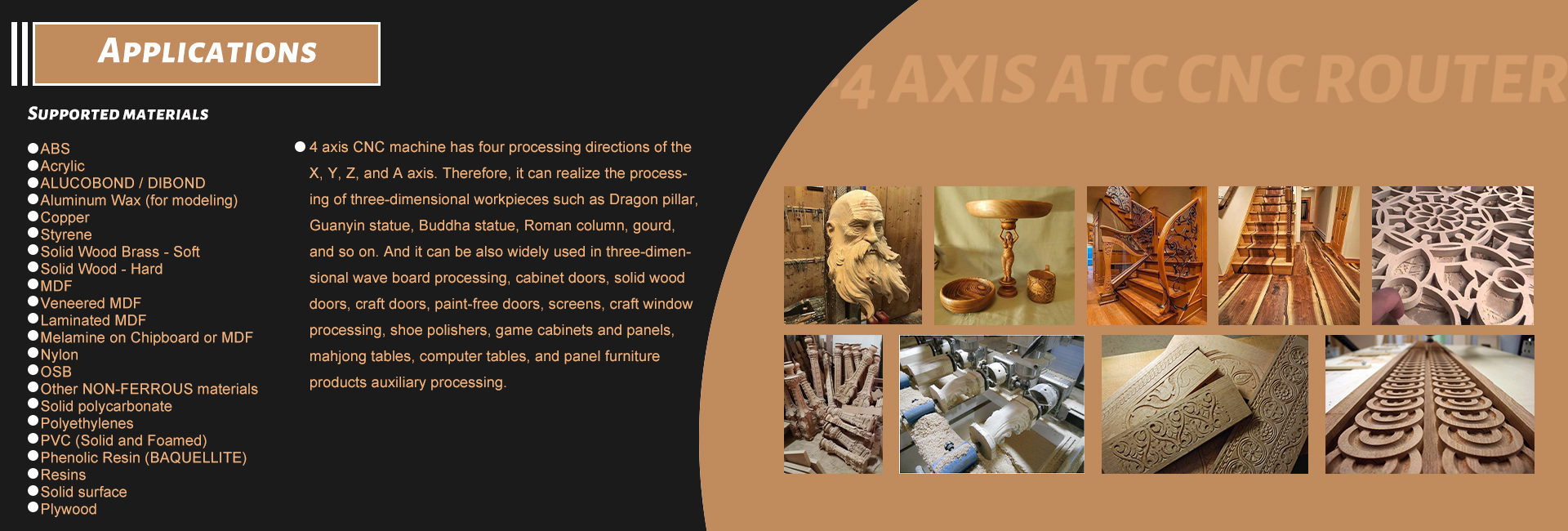

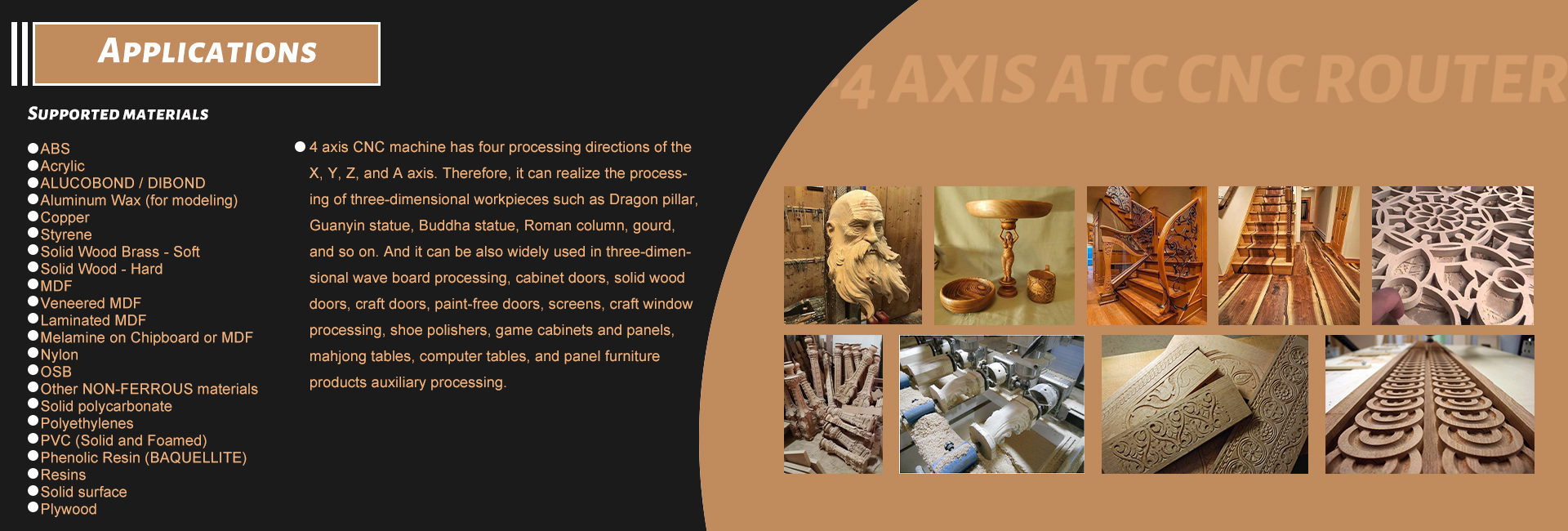

Supported materials:

ABS

Acrylic

ALUCOBOND / DIBOND

Aluminum Wax (for modeling)

Copper

Styrene

Solid Wood Brass - Soft

Solid Wood - Hard

MDF

Veneered MDF

Laminated MDF

Melamine on Chipboard or MDF

Nylon

OSB

Other NON-FERROUS materials

Solid polycarbonate

Polyethylenes

PVC (Solid and Foamed)

Phenolic Resin (BAQUELLITE)

Resins

Solid surface

Plywood

4-axis ATC CNC engraving machines are widely used in furniture manufacturing, wooden doors and cabinets, stair railings, 3D crafts, Buddha statue carving, mold processing, decorative building materials, and special-shaped workpieces. Leveraging the advantages of four-axis linkage, this machine can easily perform 3D curved surface engraving, cylindrical machining, and complex and special-shaped cutting, meeting the diverse needs of users in woodworking, advertising, crafts, and industrial production.

Supported materials:

ABS

Acrylic

ALUCOBOND / DIBOND

Aluminum Wax (for modeling)

Copper

Styrene

Solid Wood Brass - Soft

Solid Wood - Hard

MDF

Veneered MDF

Laminated MDF

Melamine on Chipboard or MDF

Nylon

OSB

Other NON-FERROUS materials

Solid polycarbonate

Polyethylenes

PVC (Solid and Foamed)

Phenolic Resin (BAQUELLITE)

Resins

Solid surface

Plywood

4-axis ATC CNC engraving machines are widely used in furniture manufacturing, wooden doors and cabinets, stair railings, 3D crafts, Buddha statue carving, mold processing, decorative building materials, and special-shaped workpieces. Leveraging the advantages of four-axis linkage, this machine can easily perform 3D curved surface engraving, cylindrical machining, and complex and special-shaped cutting, meeting the diverse needs of users in woodworking, advertising, crafts, and industrial production.

Packing:

1/ If the machine is delivered via LCL, then would be packed with wrapping film, EPE foam, and a standard export plywood box.

2/ If machine delivery via FCL, then don't need a wood box, would be packed with wrapping film and EPE foam.

Shipping:

We support machine delivery via express, air transportation, land transportation, and sea transportation.

1/ Such as some small machine, Mini CNC Router or Small CO2 Laser Machine and Fiber Laser Marking Machine, usually delivered via express and air transportation.

2/ If you wanna us to help you deliver to a domestic warehouse or Russia, Kazakhstan, etc, usually delivered via land transportation.

3/ Large machines or some countries where shipping is more convenient, usually suggest choosing sea transportation. You can choose any way you'd prefer, we also will give you some proper suggestions.

Packing:

1/ If the machine is delivered via LCL, then would be packed with wrapping film, EPE foam, and a standard export plywood box.

2/ If machine delivery via FCL, then don't need a wood box, would be packed with wrapping film and EPE foam.

Shipping:

We support machine delivery via express, air transportation, land transportation, and sea transportation.

1/ Such as some small machine, Mini CNC Router or Small CO2 Laser Machine and Fiber Laser Marking Machine, usually delivered via express and air transportation.

2/ If you wanna us to help you deliver to a domestic warehouse or Russia, Kazakhstan, etc, usually delivered via land transportation.

3/ Large machines or some countries where shipping is more convenient, usually suggest choosing sea transportation. You can choose any way you'd prefer, we also will give you some proper suggestions.