- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Working Table Size: | |

|---|---|

| Spindle Motor Power: | |

| Control system: | |

| Drive motor: | |

| Availability: | |

UT-1325P

UTECH

UT-1325P

CNC Plasma Cutting Machine / Plasma Cutter / Plasma Cut CNC

UTECH high-performance CNC plasma cutting machine is a professional equipment developed for high-efficiency metal cutting process. It combines advanced CNC system and industrial-grade plasma power supply, and has excellent cutting speed, precision and processing stability. The whole machine adopts heavy-duty welding structure and undergoes strict tempering treatment to effectively suppress deformation problems in long-term use and ensure the reliable operation of the equipment in high-load and high-frequency operations. Equipped with an arc voltage automatic height adjustment system, it can adjust the height of the cutting gun in real time to maintain stable output of the plasma arc, and can accurately cut even large-format and uneven plates. It is compatible with a variety of metal materials such as carbon steel, stainless steel, aluminum plate, galvanized plate, etc. It is widely used in sheet metal processing, machinery manufacturing, steel structure engineering, construction and other industries. It is a professional-level solution for achieving batch high-quality cutting.

Features of plasma cutting machine:

1. 1300*2500mm standard working area(can tailor made for you)

2. START control system

3. Huayuan 120A plasma generator(Optional: Hypertherm power supply)

4. Cutting Material Collection Box with wheels, for easy take out products

5. High-Quality cut performance, Fast cutting speed, high precision, and low cost.

6. With firm and reasonable structure, the machine is easy to operate and durable for use.

7. The cutting incision is thin and tidily and can avoid the second processing.

8. High configurated CNC system, auto arc-striking, and stable performance.

9. Working with computer and support G code and files of Uncanniest software (specialized in cutting metal material) (optional Fastcam software)

10. It can cut metal plate of advertising 3D lighting letter and flute profile letter with high cutting precision. (USA power is optional)

CNC Plasma Cutting Machine / Plasma Cutter / Plasma Cut CNC

UTECH high-performance CNC plasma cutting machine is a professional equipment developed for high-efficiency metal cutting process. It combines advanced CNC system and industrial-grade plasma power supply, and has excellent cutting speed, precision and processing stability. The whole machine adopts heavy-duty welding structure and undergoes strict tempering treatment to effectively suppress deformation problems in long-term use and ensure the reliable operation of the equipment in high-load and high-frequency operations. Equipped with an arc voltage automatic height adjustment system, it can adjust the height of the cutting gun in real time to maintain stable output of the plasma arc, and can accurately cut even large-format and uneven plates. It is compatible with a variety of metal materials such as carbon steel, stainless steel, aluminum plate, galvanized plate, etc. It is widely used in sheet metal processing, machinery manufacturing, steel structure engineering, construction and other industries. It is a professional-level solution for achieving batch high-quality cutting.

Features of plasma cutting machine:

1. 1300*2500mm standard working area(can tailor made for you)

2. START control system

3. Huayuan 120A plasma generator(Optional: Hypertherm power supply)

4. Cutting Material Collection Box with wheels, for easy take out products

5. High-Quality cut performance, Fast cutting speed, high precision, and low cost.

6. With firm and reasonable structure, the machine is easy to operate and durable for use.

7. The cutting incision is thin and tidily and can avoid the second processing.

8. High configurated CNC system, auto arc-striking, and stable performance.

9. Working with computer and support G code and files of Uncanniest software (specialized in cutting metal material) (optional Fastcam software)

10. It can cut metal plate of advertising 3D lighting letter and flute profile letter with high cutting precision. (USA power is optional)

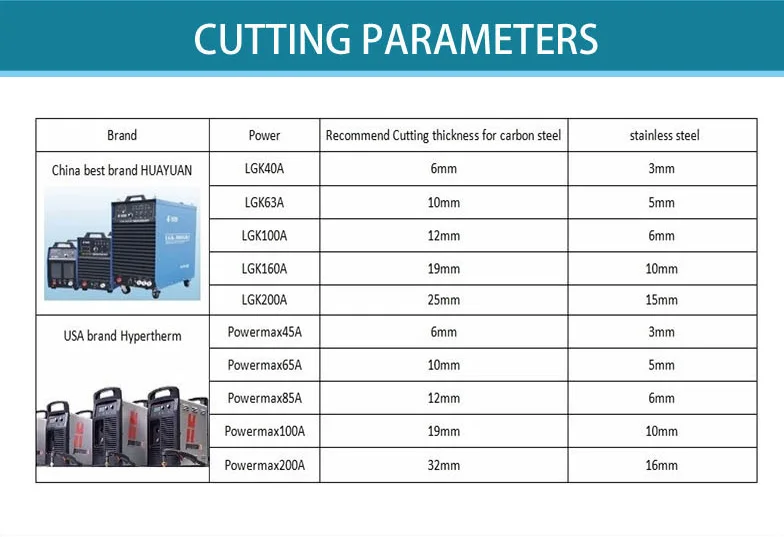

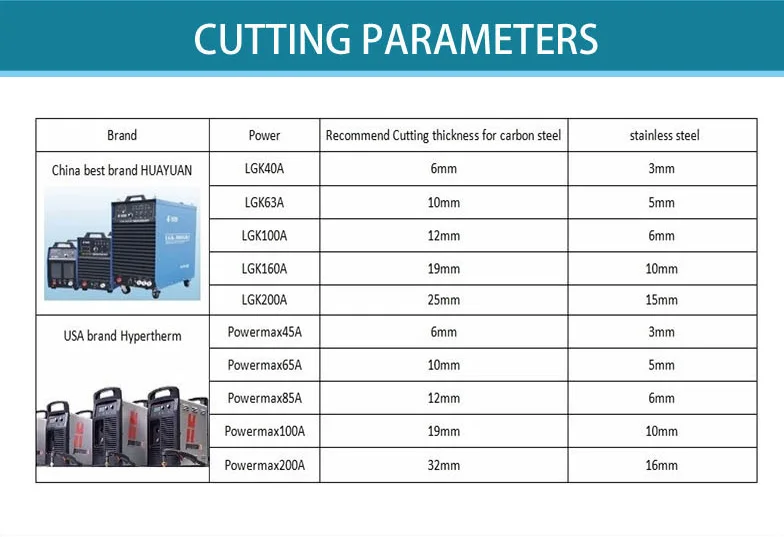

Some differences between Huayuan and Hypertherm power supply:

PS, if you're not sure which kind of plasma power is suitable for you, you can share the following information for me, I'll suggest you choose proper type.

1/ Which kind of metal materials you wanna cut?

2/ How about the cutting thickness?

Details:

| Model | UT-1325P CNC Plasma cutting machine (Other models are optional) |

| Working size | 1300x2500mm (4x8ft) (Other working sizes are optional) |

| Three axes repeat positioning accuracy | ±0.05mm |

| Process precision | ±0.35mm |

| Transmission system | X, Y: Taiwan Hiwin high-precision, zero clearance increased linear guide+ rack Z: the arc voltage control |

| Max. cutting speed | 15000mm/min |

| Working voltage | AC220/50HZ |

| Working voltage | Starfire plasma cutting system Standard high sensitivity arc voltage device |

| Software support | FASTCAM,AutoCAD,etc |

| Instruction format | G code |

| Drive system | Stepper motor |

| Plasma power supply | Huayuan 63A/120A/160A/200A. Optional, USA Hypertherm, 45A/65A/85A/105A/125A |

Application:

As an efficient metal cutting equipment, CNC plasma cutting machine is widely used in many metal processing fields, especially suitable for fast, accurate and economical cutting of medium and thick metal plates. The following are the main application directions:

Sheet metal processing: used for cutting, punching and cutting of special-shaped parts of various metal plates.

Steel structure manufacturing: suitable for cutting and cutting of large-sized steel plates in industries such as building steel structure, bridge, storage equipment, etc.

Machinery manufacturing: can cut complex structural parts such as the appearance, bracket, base of mechanical parts to improve assembly efficiency.

Shipbuilding and heavy industry: used for pre-cutting of large-format metal parts such as hull plates and cabin structural parts, with fast and stable processing.

Automobile and agricultural machinery equipment modification: widely used in customized processing of structural parts such as automobile chassis and agricultural machinery frames.

Metal decoration and artistic modeling: In metal screens, carved panels, railings and other decorative parts, CNC cutting machines can achieve fast cutting of high-precision graphics.

Pressure vessel and pipeline industry: special-shaped cutting of steel plates, flanges, end plates and other parts to improve sealing and welding efficiency.

Advertising logo production: used for cutting metal letters, logo base plates, light box brackets, etc., with clear graphics and neat edges.

Some differences between Huayuan and Hypertherm power supply:

PS, if you're not sure which kind of plasma power is suitable for you, you can share the following information for me, I'll suggest you choose proper type.

1/ Which kind of metal materials you wanna cut?

2/ How about the cutting thickness?

Details:

| Model | UT-1325P CNC Plasma cutting machine (Other models are optional) |

| Working size | 1300x2500mm (4x8ft) (Other working sizes are optional) |

| Three axes repeat positioning accuracy | ±0.05mm |

| Process precision | ±0.35mm |

| Transmission system | X, Y: Taiwan Hiwin high-precision, zero clearance increased linear guide+ rack Z: the arc voltage control |

| Max. cutting speed | 15000mm/min |

| Working voltage | AC220/50HZ |

| Working voltage | Starfire plasma cutting system Standard high sensitivity arc voltage device |

| Software support | FASTCAM,AutoCAD,etc |

| Instruction format | G code |

| Drive system | Stepper motor |

| Plasma power supply | Huayuan 63A/120A/160A/200A. Optional, USA Hypertherm, 45A/65A/85A/105A/125A |

Application:

As an efficient metal cutting equipment, CNC plasma cutting machine is widely used in many metal processing fields, especially suitable for fast, accurate and economical cutting of medium and thick metal plates. The following are the main application directions:

Sheet metal processing: used for cutting, punching and cutting of special-shaped parts of various metal plates.

Steel structure manufacturing: suitable for cutting and cutting of large-sized steel plates in industries such as building steel structure, bridge, storage equipment, etc.

Machinery manufacturing: can cut complex structural parts such as the appearance, bracket, base of mechanical parts to improve assembly efficiency.

Shipbuilding and heavy industry: used for pre-cutting of large-format metal parts such as hull plates and cabin structural parts, with fast and stable processing.

Automobile and agricultural machinery equipment modification: widely used in customized processing of structural parts such as automobile chassis and agricultural machinery frames.

Metal decoration and artistic modeling: In metal screens, carved panels, railings and other decorative parts, CNC cutting machines can achieve fast cutting of high-precision graphics.

Pressure vessel and pipeline industry: special-shaped cutting of steel plates, flanges, end plates and other parts to improve sealing and welding efficiency.

Advertising logo production: used for cutting metal letters, logo base plates, light box brackets, etc., with clear graphics and neat edges.

The machine will be packed with wrapping film, EPE foam, and wooden case(composite material box/plywood case).

SESAME CNC Router's machine legs and machine bed can be separated freely, when machine shipping, we'll dismantle the machine legs, they can help you save more shipping fee.

1. Our Wooden Case is after fumigation treatment. Needn`t timber inspection, saving shipping time.

2. All the spare parts of the machine were covered by some soft materials, mainly using Pearl Wool. Avoiding all damages that could happen in the delivery process. Then we`ll cover plastic wrap out it tightly, make sure intact of the covered soft materials, also avoiding Waterproof and rustproof.

3. The outmost is Wooden Case With Fixed Formwork.

4. The bottom of the wooden case has a firm iron jack, convenient for handling and transport.

Company:

Shandong U-May CNC Technology Co., Ltd. provides one-stop service, including design, installation, training, commissioning, maintenance and consulting. We pursue people oriented management tenet providing staff with a broad development platform, and constantly improving the company evaluation system, incentive mechanism and training system. We always emphasize on research and development. Adhering to the spirit of innovation, we will never stop to develop our own brand and new products. Your satisfaction is always what we pursue. With the expanded market, we sincerely hope to cooperate with customers from all over the world. All parts of the machine can be upgraded or changed. Please tell us your material and size. We will customize the most suitable machine for you.

The machine will be packed with wrapping film, EPE foam, and wooden case(composite material box/plywood case).

SESAME CNC Router's machine legs and machine bed can be separated freely, when machine shipping, we'll dismantle the machine legs, they can help you save more shipping fee.

1. Our Wooden Case is after fumigation treatment. Needn`t timber inspection, saving shipping time.

2. All the spare parts of the machine were covered by some soft materials, mainly using Pearl Wool. Avoiding all damages that could happen in the delivery process. Then we`ll cover plastic wrap out it tightly, make sure intact of the covered soft materials, also avoiding Waterproof and rustproof.

3. The outmost is Wooden Case With Fixed Formwork.

4. The bottom of the wooden case has a firm iron jack, convenient for handling and transport.

Company:

Shandong U-May CNC Technology Co., Ltd. provides one-stop service, including design, installation, training, commissioning, maintenance and consulting. We pursue people oriented management tenet providing staff with a broad development platform, and constantly improving the company evaluation system, incentive mechanism and training system. We always emphasize on research and development. Adhering to the spirit of innovation, we will never stop to develop our own brand and new products. Your satisfaction is always what we pursue. With the expanded market, we sincerely hope to cooperate with customers from all over the world. All parts of the machine can be upgraded or changed. Please tell us your material and size. We will customize the most suitable machine for you.